Carbon Fiber Sheets have emerged as a transformative material in Modern Manufacturing, offering unparalleled advantages in strength, weight, and adaptability. This article delves into the versatility of Carbon Fiber sheets and their applications across various industries, highlighting how they are reshaping manufacturing processes and product development.

1. Lightweight and Strong

One of the most significant advantages of Carbon fiber sheets is their exceptional Strength-to-Weight Ratio. These sheets are incredibly lightweight yet exhibit remarkable tensile strength, making them ideal for applications where weight reduction is critical. Industries such as aerospace and automotive benefit greatly from using carbon fiber sheets, as they allow for the creation of lightweight components that do not compromise on performance or safety.

2. Customizable Designs

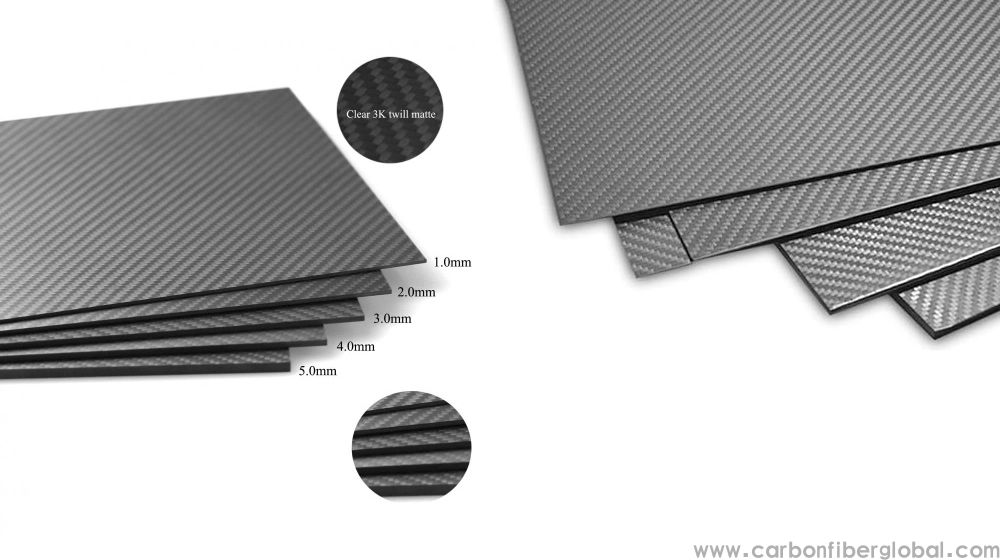

Carbon fiber sheets can be easily customized in terms of thickness, weave patterns, and resin types, allowing manufacturers to tailor them to specific needs. This adaptability enables the production of components that meet unique design requirements, making carbon fiber a preferred choice in sectors such as sports equipment, medical devices, and consumer electronics.

3. Aerospace Applications

In the aerospace industry, carbon fiber sheets are used extensively for constructing airframes, wings, and other critical components. Their lightweight nature helps reduce fuel consumption and increase efficiency, while their strength ensures safety and durability under extreme conditions. The use of carbon fiber has contributed to the development of more fuel-efficient aircraft, showcasing its impact on aviation technology.

4. Automotive Innovations

The automotive industry is increasingly incorporating carbon fiber sheets into vehicle design. From body panels to structural reinforcements, carbon fiber components help manufacturers produce lighter vehicles that improve fuel efficiency and enhance performance. As electric vehicles gain popularity, the demand for Lightweight Materials like carbon fiber is expected to rise, further driving innovation in this sector.

5. Sports Equipment Advancements

In sports, carbon fiber sheets are revolutionizing equipment design. Items such as bicycles, tennis rackets, and golf clubs benefit from the material's lightweight and durable properties, allowing for improved performance and user experience. The ability to create high-strength, lightweight gear has made carbon fiber a staple in competitive sports.

6. Consumer Electronics

The consumer electronics industry has also embraced carbon fiber sheets for product design. Smartphones, laptops, and other devices benefit from the material's lightweight nature, enhancing portability without sacrificing durability. Additionally, carbon fiber's modern aesthetic appeal adds a sleek, high-tech look to consumer products.

7. Medical Devices

Carbon fiber sheets are making significant inroads into the medical field, particularly in the development of prosthetics and orthopedic devices. Their lightweight properties enhance comfort for patients, while the material's strength ensures reliability and performance. Customizable carbon fiber components can be tailored to meet individual patient needs, improving overall outcomes.

8. Renewable Energy Solutions

In the renewable energy sector, carbon fiber sheets are being utilized in the production of wind turbine blades and solar panels. The lightweight nature of carbon fiber allows for larger and more efficient designs, contributing to improved energy generation. As the demand for sustainable energy solutions increases, carbon fiber's role in this industry is expected to grow.

9. Cost Considerations and Challenges

While carbon fiber sheets offer numerous advantages, manufacturers must also consider cost and processing challenges. The production of carbon fiber is often more expensive than Traditional materials, and the manufacturing processes can require specialized equipment. However, ongoing advancements in technology and production methods are gradually reducing costs and making carbon fiber more accessible.

10. Future Prospects

The versatility of carbon fiber sheets is driving innovation across various sectors, and their potential applications continue to expand. As research progresses and new manufacturing techniques are developed, the use of carbon fiber is likely to grow, leading to even more groundbreaking advancements in manufacturing.

Conclusion

Carbon fiber sheets are proving to be a game-changer in modern manufacturing, offering a combination of lightweight strength, customization, and durability that traditional materials cannot match. From aerospace and automotive to sports and medical devices, the versatility of carbon fiber is reshaping industries and driving innovation. As manufacturers continue to explore the potential of carbon fiber, its role in the future of manufacturing is set to become even more prominent.