As the demand for Unmanned Aerial Vehicles (UAVs) continues to grow across various industries, the materials used in their construction play a crucial role in determining performance, efficiency, and durability. Carbon Fiber has emerged as the material of choice for next-generation UAVs, thanks to its unique properties that cater to the evolving needs of the drone market. This article explores the advantages of carbon fiber and its transformative impact on UAV Design and functionality.

Exceptional Strength-to-Weight RatioOne of the standout features of carbon fiber is its remarkable strength-to-weight ratio. This characteristic allows manufacturers to create lightweight UAV frames that maintain high structural integrity. A lighter drone can fly longer distances, carry heavier payloads, and consume less energy, making carbon fiber an ideal choice for commercial and military applications.

Aerodynamic EfficiencyThe Design flexibility of carbon fiber enables the creation of streamlined shapes that enhance aerodynamic performance. Drones constructed with carbon fiber components can minimize drag and improve lift, leading to faster flight speeds and greater stability in the air. This aerodynamic efficiency is particularly beneficial for UAVs used in applications such as delivery services and agricultural monitoring.

Durability in Challenging EnvironmentsCarbon fiber is inherently resistant to environmental factors such as moisture, UV radiation, and extreme temperatures. This durability ensures that UAVs can operate effectively in a variety of conditions, from harsh outdoor environments to indoor settings. By using carbon fiber, manufacturers can reduce wear and tear on their drones, leading to longer lifespans and lower maintenance costs.

Vibration Dampening PropertiesThe ability of carbon fiber to absorb vibrations contributes to enhanced flight stability. UAVs often encounter vibrations during flight, which can negatively impact sensor performance and data quality. By integrating carbon fiber components, manufacturers can mitigate these vibrations, resulting in smoother flights and improved accuracy for applications like aerial photography and mapping.

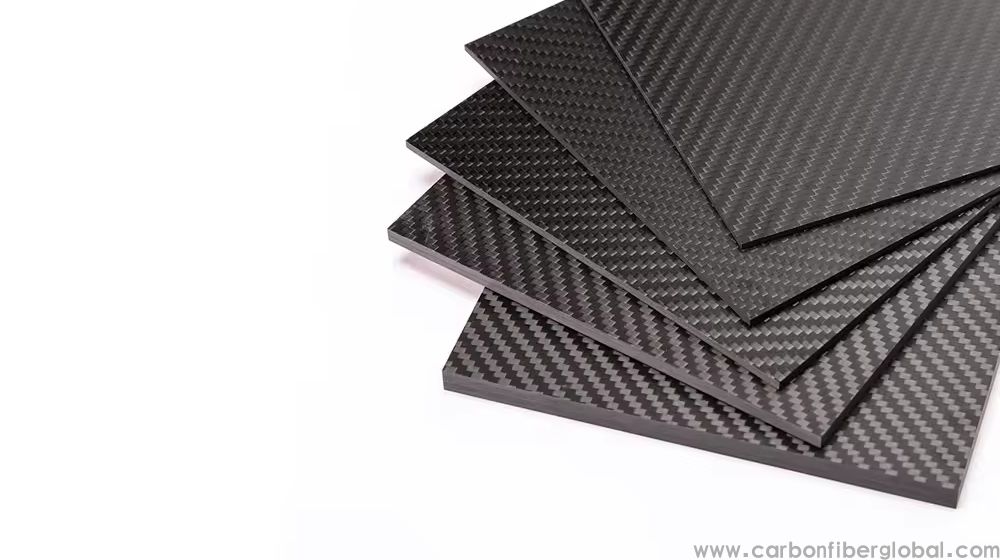

Customization for Specific ApplicationsThe versatility of carbon fiber allows for tailored designs that meet specific operational requirements. Manufacturers can customize the thickness, Weave patterns, and resin types of Carbon Fiber Sheets to optimize performance for different UAV applications. This customization capability enables innovations that address the unique needs of industries ranging from logistics to surveillance.

Advanced Propulsion SystemsCarbon fiber is also making strides in the development of advanced propulsion systems for UAVs. Lightweight Carbon Fiber propellers can significantly enhance thrust efficiency, allowing drones to achieve faster takeoffs and better maneuverability. The integration of carbon fiber in propulsion design contributes to the overall performance and responsiveness of next-generation UAVs.

Increased Payload CapacityBy reducing the overall weight of the drone through carbon fiber construction, manufacturers can design UAVs that accommodate larger payloads. This feature is essential for applications requiring advanced sensors, cameras, or delivery packages. The ability to carry more while maintaining flight performance is a critical advantage for commercial drone operators.

Sustainability and Environmental ImpactAs industries become more environmentally conscious, the sustainable qualities of carbon fiber present significant advantages. Its long lifespan and potential for recycling contribute to reduced environmental impact. By choosing carbon fiber, manufacturers can align their UAV designs with eco-friendly practices, appealing to a growing segment of environmentally aware consumers and businesses.

Modular Design and RepairabilityCarbon fiber components can be designed for modularity, allowing for easy upgrades and repairs. This flexibility is crucial in an industry where technology evolves rapidly. UAVs with modular Carbon fiber parts can be quickly modified to incorporate the latest advancements, ensuring that they remain competitive and capable in the field.

Competitive Edge in the MarketAs the UAV market becomes increasingly competitive, adopting carbon fiber technology can provide manufacturers with a significant edge. Drones that feature carbon fiber components are often perceived as more advanced, durable, and efficient, making them more attractive to consumers and businesses alike. This advantage is crucial for success in a rapidly evolving market.

Conclusion

Carbon fiber has established itself as the material of choice for next-generation UAVs, offering a unique combination of strength, lightweight properties, and design flexibility. By leveraging the advantages of carbon fiber, manufacturers can create innovative drones that meet the diverse demands of various industries. As UAV technology continues to advance, the use of carbon fiber is set to play an increasingly vital role in shaping the future of unmanned aerial vehicles.