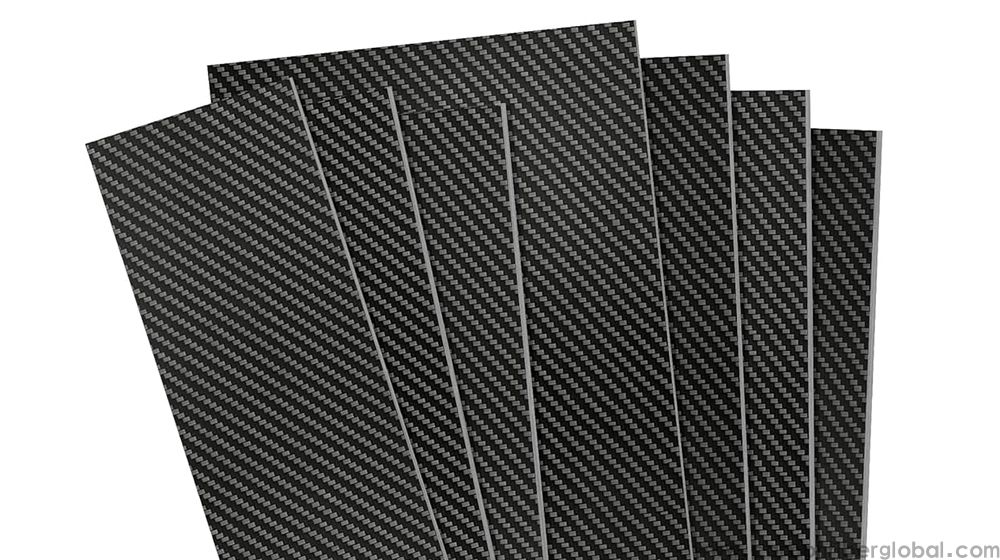

Carbon Fiber Sheets are rapidly gaining popularity across a variety of high-performance industries due to their exceptional combination of strength, lightweight properties, and durability. These unique characteristics make Carbon Fiber an ideal material for applications where performance, efficiency, and reliability are paramount. From aerospace to automotive and sports equipment manufacturing, carbon fiber is changing the way industries approach design and manufacturing challenges.

In this article, we’ll delve into the specific benefits that Carbon fiber sheets offer to high-performance industries and explore why they have become an essential material for companies striving to stay at the cutting edge.

1. Unmatched Strength-to-Weight Ratio

One of the most significant advantages of carbon fiber sheets is their incredible strength-to-weight ratio. Carbon fiber is one of the strongest materials available for its weight, providing excellent tensile strength while being remarkably lightweight. This combination allows for significant weight reduction without sacrificing structural integrity, making it especially beneficial for industries where weight is a critical factor.

For instance, in the aerospace industry, reducing the weight of an aircraft is essential for improving fuel efficiency and reducing operating costs. Similarly, the automotive industry benefits from lighter Carbon Fiber Components that improve vehicle performance, speed, and fuel efficiency. The strength of carbon fiber also ensures that the materials can withstand extreme conditions, providing enhanced durability over traditional metals like aluminum or steel.

2. Superior Durability and Resistance to Wear

Another key benefit of carbon fiber sheets is their exceptional durability. Carbon fiber is highly resistant to fatigue, wear, and corrosion. This makes it an ideal material for applications that are subject to constant stress and extreme environments, such as high-performance vehicles, machinery, and aircraft.

In industries like aerospace, where components are exposed to high temperatures and pressure, carbon fiber sheets offer outstanding thermal resistance and the ability to maintain their structural integrity under intense conditions. Similarly, in the automotive industry, Carbon fiber parts, such as body panels and frames, are highly resistant to denting and scratching, which helps preserve the aesthetic and performance of high-end vehicles over time.

The material's resistance to corrosion is also an asset in the marine industry, where exposure to saltwater and harsh environmental conditions can degrade traditional metals.

3. Enhanced Flexibility and Design Versatility

Carbon fiber sheets offer Design flexibility that allows manufacturers to create components with a wide variety of shapes, sizes, and properties. Unlike metals, which are often limited by molding and machining constraints, carbon fiber can be molded into complex forms that are not only aesthetically pleasing but also highly functional.

In industries such as sports equipment manufacturing, Custom carbon fiber sheets are used to produce lightweight yet durable products, including bicycles, skateboards, and golf clubs. The ability to tailor the material’s characteristics, such as thickness and stiffness, gives manufacturers the ability to create products that provide superior performance and comfort.

Similarly, in automotive design, carbon fiber sheets can be molded into specific shapes to optimize aerodynamics and enhance vehicle handling. In aerospace, Custom Carbon Fiber sheets are essential for crafting precision components that fit the intricate designs required for modern aircraft.

4. Heat Resistance for Extreme Environments

High-performance industries often demand materials that can withstand extreme temperatures. Carbon fiber sheets excel in environments where thermal stability is critical. Unlike metals, which can expand and contract with temperature fluctuations, carbon fiber retains its structural integrity and dimensional stability at both high and low temperatures.

This makes carbon fiber sheets invaluable for industries like aerospace, where components must endure both extreme heat during takeoff and cold temperatures at cruising altitudes. Carbon fiber's ability to withstand heat without warping or losing strength ensures that parts like jet turbine blades, wings, and heat shields continue to perform under intense stress.

In automotive racing, heat resistance is also a crucial factor, as carbon fiber parts need to maintain performance even in high-temperature environments like engine compartments or during high-speed laps on the track.

5. Environmental Benefits of Carbon Fiber

While carbon fiber has traditionally been seen as a premium material, its use is becoming more widespread as industries seek ways to reduce their environmental footprint. Carbon fiber’s lightweight nature contributes to fuel efficiency and reduced carbon emissions in sectors like aerospace and automotive.

Additionally, recycled carbon fiber is gaining traction, allowing manufacturers to reuse the material and reduce waste, which supports the growing demand for sustainable production practices. As the demand for green manufacturing practices increases, carbon fiber's recyclability offers a viable solution for companies striving to meet sustainability goals.