Carbon Fiber Sheets are increasingly becoming a staple in Industrial applications due to their exceptional Strength-to-Weight Ratio, durability, and versatility. As industries across the globe seek materials that enhance performance while reducing weight, Carbon Fiber has emerged as a solution to meet these demands. Whether in aerospace, automotive, construction, or manufacturing, Carbon fiber sheets offer a range of benefits that make them a preferred choice for high-performance applications.

In this article, we explore how carbon fiber sheets are revolutionizing industrial manufacturing and why they are the go-to material for businesses looking to enhance product performance and reduce operational costs.

1. Unmatched Strength and durability

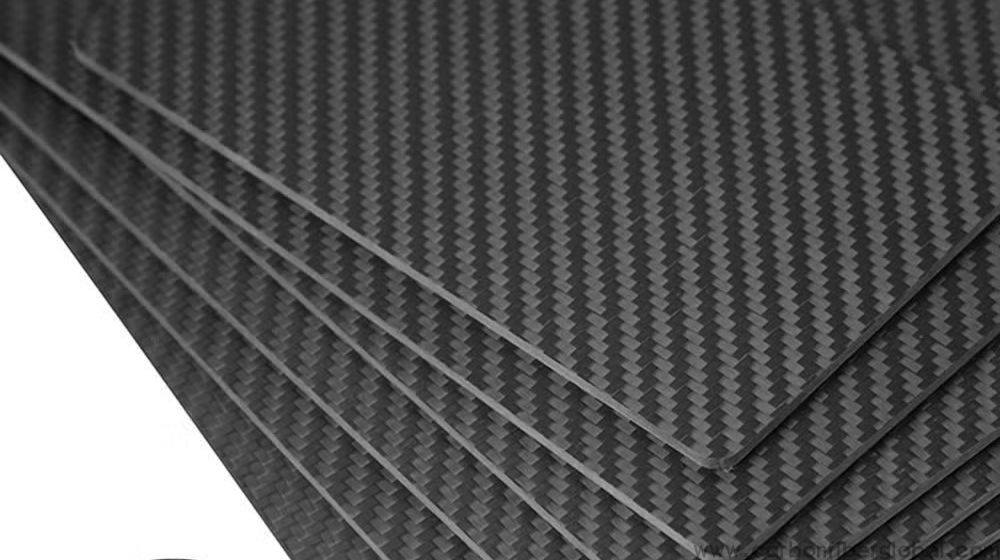

One of the primary reasons carbon fiber sheets are in high demand for industrial use is their incredible strength. Made from tightly woven carbon filaments, these sheets possess impressive tensile strength, allowing them to withstand high loads and stress. This makes them ideal for applications where structural integrity is crucial.

The strength of carbon fiber sheets is particularly advantageous in high-stress environments, where materials need to endure continuous wear and tear. In industries like automotive manufacturing, aerospace, and marine engineering, carbon fiber’s resistance to fatigue, cracking, and deformation under pressure makes it a superior choice compared to Traditional materials like steel or aluminum.

2. Lightweight and Energy-Efficient

While carbon fiber sheets are strong, they are also incredibly lightweight. The low density of carbon fiber allows manufacturers to reduce the weight of their products without sacrificing strength. This combination of strength and lightness is invaluable in industries like aerospace and automotive, where reducing weight leads to better fuel efficiency and energy savings.

For example, in the aerospace industry, reducing the weight of an aircraft can significantly lower fuel consumption and operational costs. Similarly, in the automotive sector, lighter components can lead to faster acceleration, better handling, and improved fuel efficiency, making carbon fiber sheets an attractive option for high-performance vehicles.

3. Enhanced Chemical and Heat Resistance

Carbon fiber sheets also offer exceptional resistance to corrosion, chemicals, and extreme temperatures, making them suitable for demanding environments. Whether exposed to harsh chemicals in manufacturing plants or subjected to high heat in engine components, carbon fiber does not degrade as quickly as traditional materials.

In industrial machinery, the ability to withstand heat and chemicals ensures that Carbon Fiber Components have a longer lifespan, reducing maintenance costs and downtime for manufacturers. This property also makes carbon fiber ideal for use in marine environments, where exposure to water, salt, and chemicals can quickly deteriorate other materials.

4. Versatility in Manufacturing Processes

One of the key advantages of carbon fiber sheets is their versatility. Carbon fiber can be molded into a wide range of shapes and sizes, making it suitable for various manufacturing processes. Whether you're producing large components for aerospace or smaller parts for automotive applications, carbon fiber sheets can be customized to meet the specific needs of each industry.

Molding and Laminating: Carbon fiber sheets can be layered and laminated to create customized thicknesses or tailored properties. This flexibility allows manufacturers to design components with specific mechanical properties based on the demands of the application.

Cutting and Shaping: As previously mentioned, carbon fiber sheets can be precisely cut, shaped, and finished using tools like laser cutters, CNC routers, or waterjet cutting. This ability to produce complex geometries makes carbon fiber an ideal material for industries that require intricate, custom-designed components.

3D Printing: With advances in 3D printing technology, carbon fiber composites are now being used in additive manufacturing. This allows for even greater customization and faster prototyping, providing a competitive edge in industries like automotive manufacturing and engineering design.

5. Applications of carbon fiber Sheets in Industry

The versatility and strength of carbon fiber sheets make them highly valuable across a wide range of industrial applications. Here are some key areas where carbon fiber is transforming manufacturing:

Aerospace: Carbon fiber is commonly used for creating lightweight yet strong components for aircraft and spacecraft. From aircraft wings to engine parts, the material’s strength and low weight are critical for ensuring efficiency and safety in flight.

Automotive: In the automotive industry, carbon fiber sheets are used in manufacturing high-performance vehicles. These vehicles benefit from reduced weight, enhanced fuel efficiency, and improved handling. Carbon fiber is also used in the production of motorcycle components, such as frames, fenders, and fairings.

Marine: Carbon fiber sheets are used in constructing boats, yachts, and submarines where high strength and low weight are crucial for performance on the water. The material’s resistance to corrosion also makes it ideal for marine applications.

Industrial Machinery: In manufacturing machinery, carbon fiber sheets are used to produce parts that require high rigidity and low weight. This includes components for robotics, automated systems, and manufacturing equipment.

Construction: Carbon fiber is increasingly being used for structural reinforcement in buildings and infrastructure. Carbon fiber sheets are used to reinforce concrete and steel beams, providing additional strength while keeping the overall weight of the structure down.

Sports Equipment: From bicycles and skateboards to golf clubs and tennis rackets, carbon fiber’s use in sports equipment is becoming more prevalent. It allows manufacturers to produce high-performance gear that is both lightweight and durable.

6. Cost Considerations

While carbon fiber sheets offer numerous benefits, they do come with a higher initial cost compared to traditional materials. However, the long-term benefits—such as reduced maintenance costs, improved energy efficiency, and extended product life—often outweigh the initial investment. For businesses looking to scale operations and achieve long-term savings, carbon fiber is a worthwhile investment.

Many companies are also exploring ways to reduce costs by integrating carbon fiber composites with other materials or using recycled carbon fiber to make production more cost-effective while maintaining the material’s high-performance attributes.