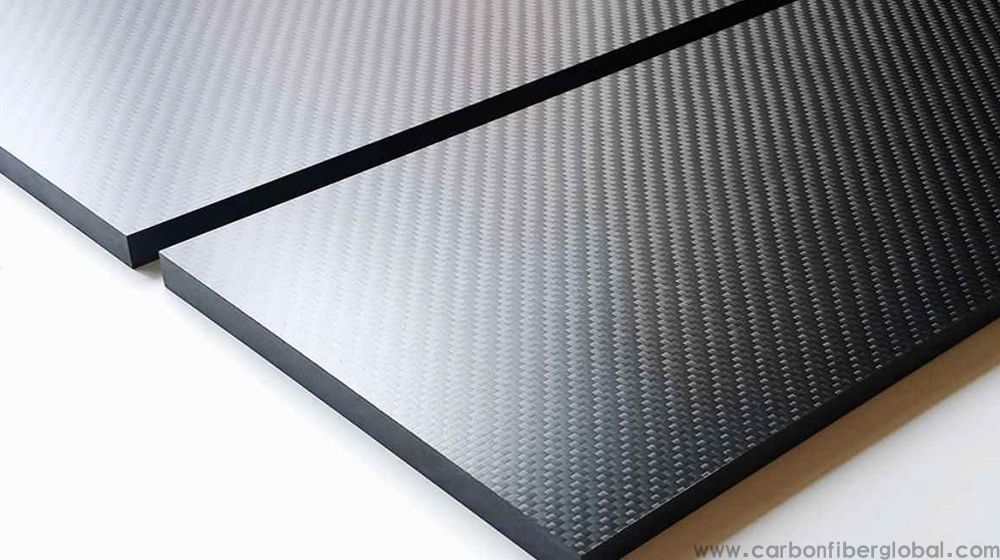

In today's fast-paced and innovation-driven world, the demand for Lightweight Materials has never been greater. Carbon Fiber Sheets have emerged as a leading solution, offering unmatched strength, versatility, and performance across various industries. This article delves into the reasons why Carbon Fiber sheets are paving the way for the future of Lightweight design.

1. Exceptional Strength-to-Weight Ratio

One of the most significant advantages of Carbon fiber sheets is their incredible strength-to-weight ratio. Carbon fiber is five times stronger than steel while being significantly lighter. This makes it an ideal material for applications where weight reduction is critical without compromising structural integrity, such as in aerospace and automotive industries.

2. Versatile Applications

Carbon fiber sheets can be tailored to suit a wide range of applications. From aircraft components and high-performance vehicles to sports equipment and consumer electronics, the versatility of carbon fiber allows for innovative designs that enhance performance. Customization options enable manufacturers to create specific shapes, sizes, and thicknesses to meet unique project requirements.

3. Enhanced Fuel Efficiency

In sectors like aerospace and automotive, reducing weight directly correlates to improved fuel efficiency. Lighter materials lead to lower energy consumption, which is essential for sustainability and cost-effectiveness. As industries push towards greener solutions, carbon fiber sheets provide a practical way to achieve these goals.

4. Resistance to Corrosion and Environmental Damage

Carbon fiber sheets boast excellent resistance to corrosion, moisture, and UV damage. This durability extends the lifespan of components, reducing maintenance costs and enhancing reliability. Industries operating in harsh environments, such as marine or construction, benefit significantly from the protective qualities of carbon fiber.

5. Design flexibility

The ability to easily mold and shape carbon fiber sheets allows for more creative and efficient designs. Complex geometries that traditional materials struggle to accommodate can be effortlessly achieved with carbon fiber. This design flexibility fosters innovation, enabling engineers and designers to push the boundaries of what's possible.

6. Lightweight Alternatives to Traditional Materials

As industries seek to reduce reliance on heavy materials, carbon fiber sheets present a compelling alternative. Traditional materials like metals and plastics can be replaced or supplemented with carbon fiber, resulting in lighter, more efficient products. This shift not only improves performance but also addresses sustainability concerns by minimizing resource consumption.

7. Advancements in Manufacturing Technology

Recent advancements in manufacturing processes have made carbon fiber more accessible and cost-effective. Techniques such as automated fiber placement (AFP) and continuous fiber-reinforced thermoplastics (CFRTP) are enhancing production efficiency and reducing costs, making carbon fiber sheets an attractive option for manufacturers.

8. Growing Industry Adoption

With the automotive, aerospace, and sports industries increasingly adopting carbon fiber sheets, other sectors are beginning to recognize their potential. As more companies explore the benefits of lightweight design, the demand for Carbon Fiber Solutions is set to grow, solidifying its role as a future material of choice.

Conclusion

Carbon fiber sheets represent the future of lightweight design, offering a combination of strength, versatility, and performance that traditional materials cannot match. As industries continue to prioritize innovation and sustainability, the adoption of carbon fiber sheets is poised to rise, leading to breakthroughs in design and functionality across various sectors.