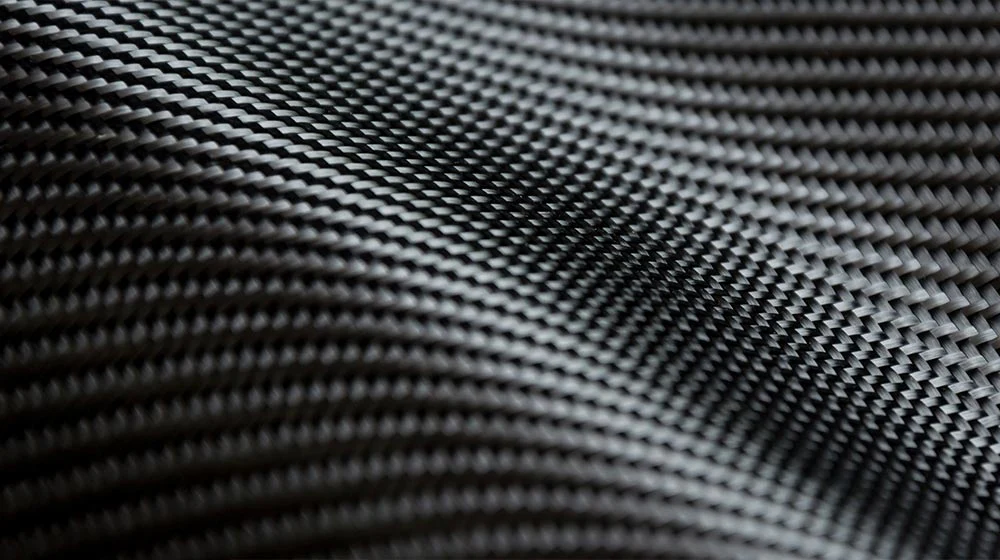

Carbon Fiber Sheets have become an essential material in modern engineering, particularly in industries like aerospace and automotive, where weight reduction and strength are critical. Traditional materials such as steel and aluminum, though strong, are much heavier, limiting efficiency and performance. Carbon Fiber offers a superior alternative by providing exceptional strength at a fraction of the weight, making it a preferred choice for advanced applications.

What Makes Carbon fiber sheets So Valuable?

- High Strength-to-Weight Ratio: Carbon fiber sheets provide greater tensile strength than many metals, while being much lighter. This makes them ideal for applications where performance and fuel efficiency matter, such as aircraft components and high-end cars.

- Corrosion Resistance: Unlike metals, carbon fiber does not rust or corrode, making it highly durable in harsh environments, including aerospace conditions.

- Design flexibility: Carbon fiber sheets are easy to mold, cut, and integrate into complex designs, making them a favorite among engineers.

- Thermal Stability: The material performs well across extreme temperature ranges, making it suitable for aerospace systems exposed to both hot and cold conditions.

Carbon Fiber in Aerospace

In the aerospace industry, reducing weight without compromising strength is a top priority. Carbon fiber sheets are used extensively in aircraft fuselages, wings, and internal components to minimize weight and enhance fuel efficiency. For example, modern aircraft, including those produced by Boeing and Airbus, rely heavily on carbon fiber to meet stringent performance and environmental regulations. With these materials, airlines can lower fuel consumption and reduce emissions, contributing to greener aviation.

Carbon Fiber in Automotive Applications

In the automotive world, the pursuit of speed and efficiency drives innovation. High-performance vehicles, including supercars and electric vehicles, use carbon fiber sheets to replace traditional steel components. The reduced weight allows for better acceleration, handling, and fuel economy. For electric cars, the use of carbon fiber sheets in structural parts extends battery range by making the vehicle lighter. Additionally, carbon fiber is gaining popularity in motorsports, where every gram matters, helping race teams achieve better lap times.

CarbonFiberGlobal: Your Partner in Carbon Fiber Innovation

At CarbonFiberGlobal, we take pride in producing Premium Carbon Fiber sheets that meet the exacting standards of the aerospace and automotive industries. Our T800 carbon fiber sheets offer unmatched strength, stiffness, and weight savings, making them ideal for demanding applications. Backed by advanced manufacturing technology and rigorous quality control, our sheets ensure optimal performance even in the most challenging environments.

As industries continue to evolve, CarbonFiberGlobal stays ahead of the curve by offering customized solutions tailored to our clients’ needs. Whether you require pre-cut sheets for automotive projects or large-scale production for aerospace components, we have the expertise and facilities to deliver. Our carbon fiber solutions have been trusted by businesses worldwide, helping them push the limits of performance and efficiency.

Conclusion

Carbon fiber sheets are not just materials—they are enablers of innovation in industries where performance matters most. From aircraft to electric vehicles, the ability to reduce weight while maintaining strength gives engineers the freedom to design with fewer limitations. At CarbonFiberGlobal, we are committed to helping our clients achieve their goals by providing the highest quality Carbon Fiber Products available on the market. With our expertise and advanced technologies, we are your trusted partner in building the future with carbon fiber.