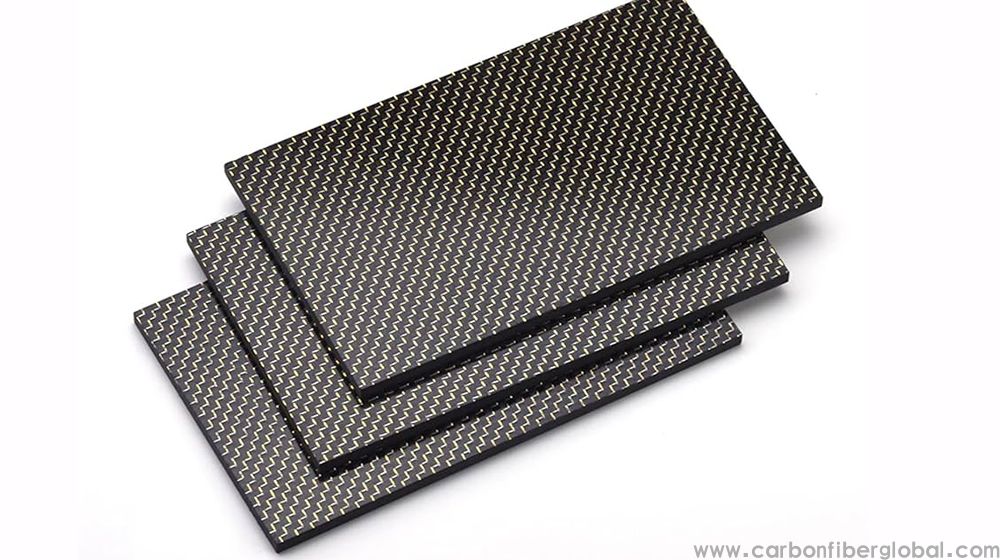

The advent of custom Carbon Fiber Sheets has been a game-changer in the design and manufacturing of both aerospace and automotive components. Known for their unique combination of lightweight properties and exceptional strength, Carbon Fiber materials are increasingly being tailored to meet the specific needs of these high-performance industries. By customizing Carbon fiber sheets, manufacturers can create parts and components that not only meet exacting performance standards but also push the boundaries of innovation and design.

This article explores how Custom carbon fiber sheets are transforming the aerospace and automotive sectors, driving advancements in efficiency, performance, safety, and sustainability.

1. Aerospace: Reducing Weight, Enhancing Efficiency, and Performance

The aerospace industry has long been a pioneer in adopting Lightweight Materials to optimize fuel efficiency, speed, and overall performance. As the demand for more fuel-efficient and eco-friendly aircraft increases, carbon fiber sheets have emerged as a top choice due to their impressive Strength-to-Weight Ratio.

Tailored Carbon Fiber for Aircraft Structures

Custom Carbon Fiber sheets are used to design a variety of aerospace components, including aircraft fuselages, wings, control surfaces, and engine components. By using carbon fiber in place of traditional materials like aluminum, manufacturers can reduce the overall weight of the aircraft, improving fuel efficiency and cutting emissions—critical factors in today’s environmentally-conscious aviation industry.

Customized carbon fiber sheets can be engineered to meet specific strength, stiffness, and heat resistance requirements, ensuring that parts are both lightweight and durable enough to withstand the harsh conditions of flight. In particular, custom solutions allow aerospace engineers to optimize material properties for critical performance areas, such as aerodynamic efficiency, load-bearing capacity, and thermal stability.

Moreover, carbon fiber’s corrosion resistance makes it an ideal material for aircraft components, reducing maintenance costs and improving the overall longevity of the aircraft.

Revolutionizing Aircraft Design

The use of custom carbon fiber sheets has also opened up new possibilities for innovative design. Unlike metals, carbon fiber can be molded into more complex shapes with greater precision, allowing for the creation of streamlined, aerodynamically efficient structures. This flexibility is particularly advantageous for creating next-generation aircraft that are not only more efficient but also capable of reaching higher speeds and offering better passenger comfort.

2. Automotive: Performance, Safety, and Fuel Efficiency

In the automotive industry, custom carbon fiber sheets are transforming vehicle design by providing lightweight solutions without compromising strength or safety. The automotive sector, especially in high-performance and luxury vehicles, is increasingly turning to carbon fiber composites to enhance vehicle performance, reduce fuel consumption, and improve safety features.

Custom Carbon Fiber for Vehicle Weight Reduction

Reducing the weight of a vehicle is one of the most effective ways to improve its fuel efficiency and handling. Custom carbon fiber sheets are used to manufacture lightweight components such as body panels, chassis, frame structures, and interior parts. By replacing heavier materials, such as steel or aluminum, with custom carbon fiber, automotive manufacturers can create cars that are faster, more fuel-efficient, and environmentally friendly.

In sports cars and racing vehicles, carbon fiber is essential for achieving high speeds while maintaining safety and stability. Tailoring carbon fiber to the specific needs of the vehicle allows manufacturers to adjust the material’s properties to achieve the perfect balance between rigidity and flexibility, ensuring maximum performance and safety.

Improving Vehicle Safety and Durability

One of the key benefits of carbon fiber is its strength and impact resistance. Custom carbon fiber sheets are used to reinforce critical vehicle parts, including crash structures, bumper beams, and safety cages. The material’s high impact resistance ensures that vehicles can better protect passengers in the event of a crash. The lightweight nature of carbon fiber also allows manufacturers to design safer, crumple zones that absorb and dissipate energy during collisions, reducing the force of impact.

Additionally, custom carbon fiber’s corrosion resistance means that automotive components are less prone to rust and wear, extending the life of the vehicle and reducing maintenance costs.

Aesthetic Design and Performance Enhancement

Beyond functionality, custom carbon fiber sheets also offer aesthetic advantages. The unique look of carbon fiber, with its sleek, modern appearance, is often used in high-performance sports cars to create a distinctive, premium feel. Carbon fiber components can be integrated into interior designs, exterior trims, and even **customized lightweight wheels to give vehicles a sporty and premium appeal.

The ability to tailor the appearance and characteristics of carbon fiber allows manufacturers to not only improve performance but also deliver vehicles with cutting-edge, aesthetic appeal that resonates with performance enthusiasts and luxury car buyers.

3. The Future of Carbon Fiber in Aerospace and Automotive Design

As both the aerospace and automotive industries continue to push the boundaries of innovation, Custom Carbon Fiber Solutions will play an increasingly important role. In the aerospace sector, next-generation aircraft are expected to use even more advanced, Lightweight Carbon Fiber composites to further improve fuel efficiency and reduce environmental impact. For automotive manufacturers, the use of custom carbon fiber sheets is expected to grow as more companies seek ways to improve fuel efficiency, vehicle performance, and sustainability.

The integration of advanced manufacturing technologies, such as 3D printing and automated layup processes, will allow for even more precise customization of carbon fiber materials, unlocking new possibilities for complex component designs, improved performance, and cost-efficiency.

Conclusion: A Material Revolutionizing Aerospace and Automotive Design

Custom carbon fiber sheets have already had a significant impact on the aerospace and automotive industries, revolutionizing the way manufacturers design and produce high-performance components. The material’s exceptional strength, lightweight properties, and customization potential have enabled aerospace engineers and automotive designers to create more efficient, durable, and aerodynamic products.

In aerospace, carbon fiber’s ability to reduce weight while improving strength and efficiency has led to more sustainable and advanced aircraft designs. In the automotive sector, custom carbon fiber sheets are enhancing vehicle performance, safety, and fuel efficiency, while also enabling designers to create sleek, aesthetically pleasing vehicles that stand out in the market.

As both industries continue to innovate, the role of custom carbon fiber solutions will only grow, driving the next wave of high-performance engineering in aerospace and automotive design.