In today’s rapidly advancing industrial world, the demand for Lightweight Materials that don’t compromise on strength or performance is greater than ever. Carbon Fiber Sheets are leading this charge, offering a revolutionary solution to industries that require materials capable of delivering high strength, low weight, and exceptional durability. From aerospace to automotive, sports equipment to construction, Carbon Fiber’s unique properties are redefining what is possible in product design and manufacturing.

1. Superior Strength-to-Weight Ratio

One of the most remarkable attributes of carbon fiber is its strength-to-weight ratio. It is both incredibly strong and exceptionally light compared to Traditional materials like steel or aluminum. Carbon fiber is made from thin, strong crystalline filaments, which give it its impressive tensile strength while maintaining a fraction of the weight. This property makes it ideal for industries where reducing weight without sacrificing performance is critical.

For example, in the automotive industry, using Carbon fiber sheets for vehicle bodies and frames allows manufacturers to significantly reduce the overall weight of the car, which in turn enhances fuel efficiency and overall performance. Lighter vehicles experience less drag and improved acceleration, offering a competitive edge in both the luxury and sports car markets.

2. Aerospace Advancements

The aerospace industry has long been at the forefront of utilizing lightweight materials, and carbon fiber has become a material of choice for building aircraft parts. In airplanes, carbon fiber sheets are used in everything from wings to fuselages and tail sections, contributing to a significant reduction in weight. The lower weight improves fuel efficiency, reduces operational costs, and enhances the payload capacity of aircraft.

Carbon fiber’s corrosion resistance also plays a crucial role in the aerospace sector, where the material’s ability to withstand extreme conditions and environmental stress makes it perfect for high-performance, long-lasting components. This not only reduces maintenance needs but also increases the operational lifespan of aircraft.

3. Revolutionizing Sports Equipment

In sports equipment, carbon fiber’s lightweight properties are transforming products such as bicycles, golf clubs, tennis rackets, and ski poles. Athletes benefit from the reduced weight and increased strength, which contribute to improved performance, speed, and control.

For example, carbon fiber bicycles offer riders a lightweight yet stiff frame, providing better control on rough terrains and enhancing overall ride efficiency. Similarly, golf clubs made from carbon fiber are stiffer and more responsive, allowing players to achieve greater power and accuracy.

4. Durability and Longevity

Beyond its lightweight nature, carbon fiber is known for its exceptional durability. Unlike metals that may suffer from rust or fatigue over time, carbon fiber maintains its strength and integrity for long periods, even under harsh conditions. This makes it ideal for products exposed to extreme temperatures, moisture, or mechanical stress, such as in marine applications, construction, and military equipment.

For example, carbon fiber reinforced plastics (CFRP) are increasingly being used in structural components for buildings and bridges, where they provide a high level of strength without the added weight of traditional steel reinforcement. This reduces the load on foundations, while also extending the lifespan of the structures.

5. Environmental Benefits

As industries become more focused on sustainability, carbon fiber sheets are emerging as a green alternative to heavier, more resource-intensive materials. Though the production of carbon fiber is energy-intensive, its lightweight properties offer significant fuel savings and reduced emissions over the lifetime of the product. In vehicles and aircraft, for instance, the reduced weight leads to lower fuel consumption, directly contributing to a reduction in carbon emissions.

Furthermore, ongoing advancements in carbon fiber recycling technologies are helping to mitigate some of the environmental impacts associated with its production. Companies are exploring ways to reuse and recycle carbon fiber materials, which will make the manufacturing process more sustainable and reduce waste.

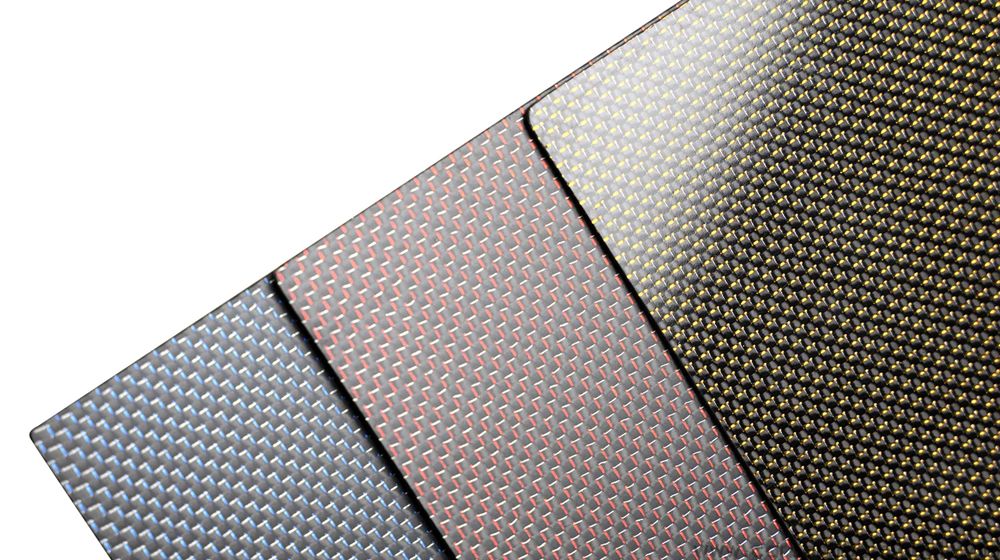

6. Customization and Flexibility in Manufacturing

Carbon fiber sheets are highly versatile and can be customized to meet the specific needs of different industries. They can be produced in various forms—flat sheets, pre-preg (pre-impregnated fibers), or 3D-printed composites—allowing manufacturers to tailor Carbon Fiber Products to specific shapes, sizes, and properties required for each application.

In industries like medical device manufacturing, custom prosthetics and orthotic devices are being made from carbon fiber to offer lightweight, durable, and personalized solutions for patients. This customization allows for the creation of highly specialized components, which is a significant advantage in advanced manufacturing and product design.

7. Carbon Fiber’s Role in Sustainability and Green Innovation

With increasing pressure on industries to move toward more sustainable practices, carbon fiber sheets play a key role in green innovation. As lightweight materials continue to replace heavier, more energy-consuming materials like metal, carbon fiber is helping companies reduce their environmental footprint.

In addition, carbon fiber is being used in renewable energy technologies such as wind turbine blades, where its strength and low weight contribute to higher energy output and reduced operational costs. The use of carbon fiber in renewable energy infrastructure is a growing field that promises to drive further adoption of lightweight materials in sustainable technologies.