In today's high-performance material market, Carbon Fiber plates and sheets stand out as vital components for various industries, including aerospace, automotive, and sports equipment. Their unique properties make them ideal for applications requiring exceptional strength and lightweight performance.

Benefits of Carbon Fiber:Carbon fiber is known for its impressive Strength-to-Weight Ratio, making it significantly stronger than traditional materials like aluminum and steel while being much lighter. This characteristic is particularly beneficial in industries where reducing weight is crucial for performance and efficiency, such as in aerospace and automotive applications.

Durability and Resistance:One of the key advantages of carbon fiber plates and sheets is their resistance to corrosion, chemicals, and environmental factors. This durability ensures a longer lifespan for products, reducing maintenance costs and enhancing reliability. Whether used in structural components or intricate designs, carbon fiber maintains its integrity under various conditions.

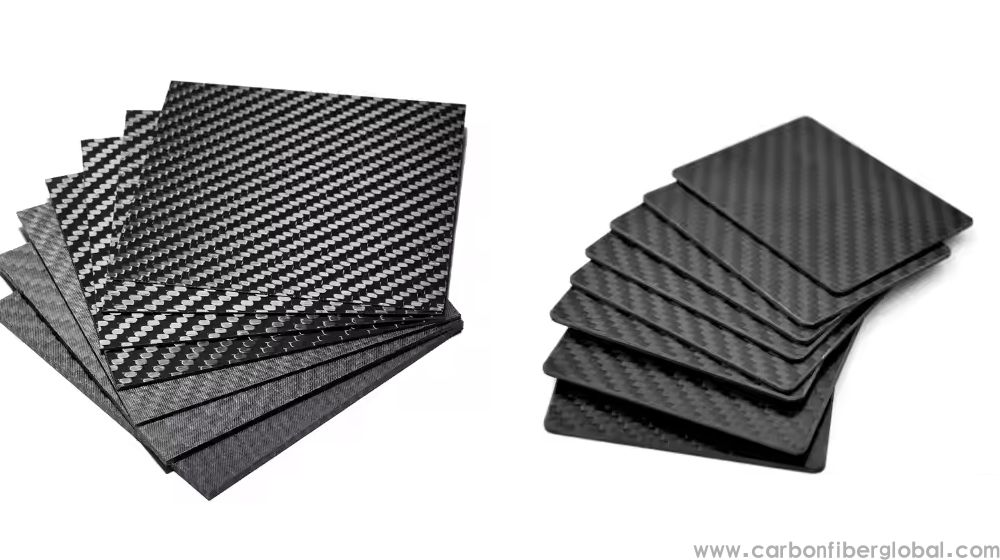

Manufacturing Process:The production of high-quality Carbon Fiber Sheets involves several critical steps. Initially, raw carbon fibers are woven into fabric, which is then layered and impregnated with resin. This composite material is subjected to heat and pressure in a curing process that solidifies its structure. For wholesalers, understanding the manufacturing techniques can help in sourcing quality products that meet specific industry standards.

Applications Across Industries:Carbon fiber plates and sheets are widely used across multiple sectors:

- Aerospace: For lightweight structural components that enhance fuel efficiency.

- Automotive: In performance vehicles for parts like body panels and chassis.

- Sports Equipment: In items such as bicycles, tennis rackets, and high-performance skis, where weight and strength are paramount.

- Industrial applications: In machinery components and tooling that require high stiffness and low weight.

Choosing a Reliable Supplier:For wholesalers, sourcing Carbon Fiber Products from reputable manufacturers is essential. Look for suppliers with certifications and a track record of quality assurance. This not only ensures that the materials meet industry standards but also fosters long-term partnerships that can enhance business growth.

Market Trends:The demand for carbon fiber products is projected to grow as industries continue to seek materials that offer better performance and sustainability. Wholesalers should stay informed about market trends, emerging technologies, and advancements in Carbon Fiber Applications to remain competitive.

In conclusion, High-Quality Carbon Fiber plates and sheets are crucial in modern manufacturing. By investing in these materials, wholesalers can provide their clients with products that enhance performance, durability, and overall value. Understanding the benefits, manufacturing processes, and market dynamics of carbon fiber will position wholesalers to capitalize on this growing industry.