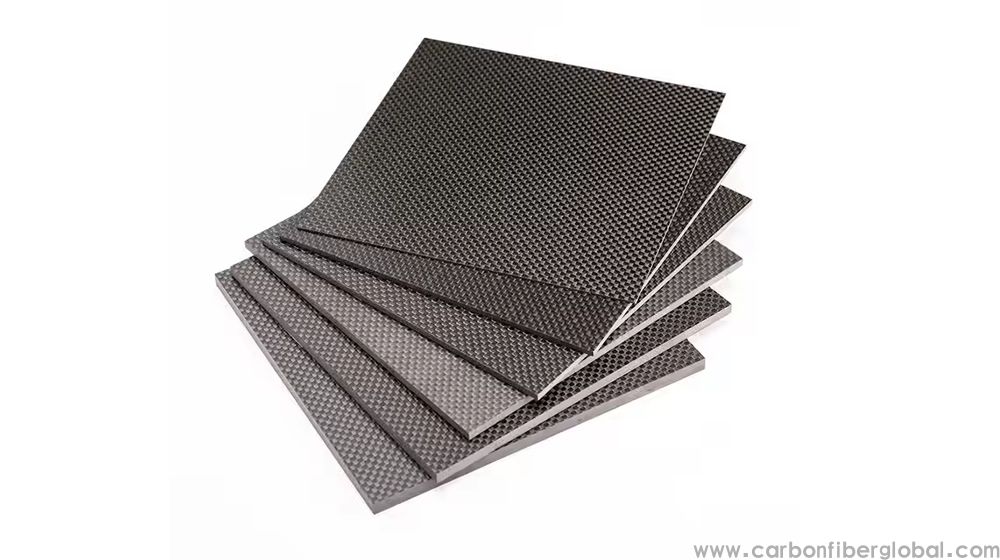

Flexible Carbon Fiber Sheets offer a unique combination of strength, lightweight properties, and adaptability, making them an excellent choice for applications requiring both durability and flexibility. Unlike rigid Carbon Fiber panels, these sheets are designed to bend and conform to curved surfaces while maintaining the superior characteristics of traditional carbon fiber.

Key Features of Flexible Carbon fiber sheets

High Strength-to-Weight Ratio

flexible carbon fiber sheets retain the incredible Strength and durability of traditional carbon fiber while being much lighter than metals like steel or aluminum.Flexibility and Conformity

These sheets can bend without breaking, making them ideal for projects involving curved or irregular surfaces.Durability

They are resistant to corrosion, temperature fluctuations, and UV exposure, ensuring long-term reliability in various environments.Thin and Lightweight

Typically available in thicknesses ranging from 0.2mm to 1mm, flexible sheets are exceptionally thin, allowing for easy handling and integration.Customizable Appearance

Available in different finishes, such as glossy, matte, or textured, they provide both functional and aesthetic versatility.

Applications of Flexible Carbon Fiber Sheets

Automotive

Used in wrapping components like dashboards, trim, and custom interior panels. The flexibility allows for seamless integration into curved designs.Aerospace

Ideal for lightweight and flexible reinforcements in aircraft interiors, such as seats or non-structural panels.Sports and Recreation

Commonly found in high-performance equipment, such as protective gear, skis, or bicycle frames that benefit from both strength and adaptability.DIY Projects

Popular among hobbyists for crafting unique items, such as phone cases, wallets, and decorative elements.Industrial applications

Used in vibration damping, flexible tooling, and as reinforcement layers for composite materials.

How to Work with Flexible Carbon Fiber Sheets

Flexible carbon fiber sheets are relatively easy to handle with the right tools and techniques:

Cutting:

Use sharp scissors or a utility knife for thin sheets. For thicker sheets, diamond-coated or carbide tools are recommended.Bonding:

Epoxy adhesives work best for attaching sheets to other surfaces. Ensure the surface is clean and free from debris for optimal adhesion.Forming:

These sheets can be shaped around curves and contours. Applying heat during the process can improve conformity in some cases.

Choosing the Right Flexible Carbon Fiber Sheet

When selecting a flexible carbon fiber sheet, consider the following factors:

- Thickness: Thinner sheets are more pliable but may have reduced strength compared to thicker options.

- Weave Style: Twill weaves offer greater flexibility than plain weaves and are visually appealing.

- Finish: Choose a finish that matches your aesthetic and functional requirements.

Where to Buy Flexible Carbon Fiber Sheets

Flexible carbon fiber sheets are available through specialized composite material suppliers, such as DragonPlate, Protech Composites, and Rock West Composites. Many online platforms, including Amazon and Alibaba, also offer a range of options at competitive prices.

Conclusion

Flexible carbon fiber sheets combine the high-performance characteristics of carbon fiber with the versatility of a bendable material. Whether you're tackling an advanced engineering project or creating custom designs, these sheets provide a perfect balance of strength, durability, and adaptability. Their unique properties make them indispensable for industries ranging from automotive to aerospace and beyond.