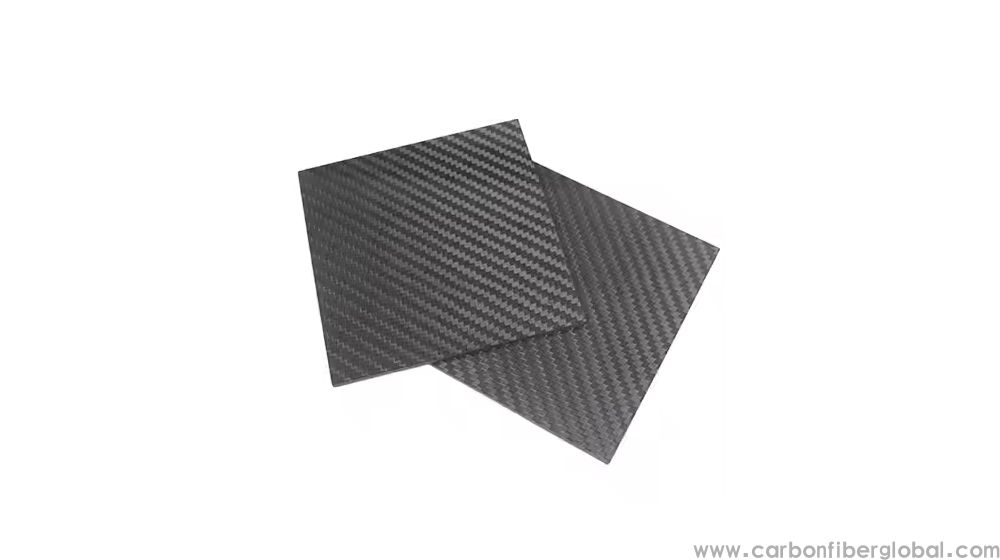

In the world of automotive, aerospace, and consumer products, Carbon Fiber is often celebrated for its exceptional Strength-to-Weight Ratio, aesthetic appeal, and high-performance qualities. However, for some applications, genuine carbon fiber might not be necessary, or it might be cost-prohibitive. This has led to the rise of fake Carbon Fiber Sheets, which are materials designed to imitate the look and feel of true carbon fiber without offering the same performance characteristics.

Understanding what fake Carbon fiber sheets are, how they differ from real carbon fiber, and where they can be used is essential if you're considering them for your next project.

What Are fake carbon fiber sheets?

Fake carbon fiber sheets are typically made from materials that mimic the appearance of carbon fiber but lack its signature strength, durability, and lightness. These materials are often used for aesthetic purposes rather than functional applications. Fake carbon fiber sheets are usually manufactured using different technologies and materials, including:

Vinyl Wraps:

- Description: These are plastic sheets with a carbon fiber texture that can be applied over other surfaces to simulate the appearance of carbon fiber.

- Features: Vinyl wraps are often self-adhesive, making them easy to apply to various surfaces like cars, laptops, or furniture. They are flexible and lightweight, but they don't offer the structural benefits of real carbon fiber.

- Use Cases: Widely used in automotive customization, interior decoration, and product design to create a carbon fiber look on a budget.

Carbon Fiber-Like Fabrics:

- Description: Some fabrics are woven to resemble carbon fiber patterns but are made from synthetic fibers like polyester or nylon instead of carbon fiber strands.

- Features: These fabrics may be lighter than actual carbon fiber, but they are not as durable and are often used for fashion items or lower-impact applications.

- Use Cases: These fabrics are often used in fashion items like bags, wallets, and clothing, or for crafting purposes.

Fiberglass Sheets with Carbon Fiber Appearance:

- Description: Fiberglass sheets may be coated with a thin layer that resembles carbon fiber. The fiberglass underneath provides strength, but it doesn’t have the same lightweight properties as real carbon fiber.

- Features: These sheets are often cheaper than true carbon fiber and can be molded or cut easily, making them ideal for less demanding applications.

- Use Cases: Commonly used in DIY projects, interior decoration, or for applications where the aesthetic is more important than performance.

Differences Between Fake and real carbon fiber sheets

While fake carbon fiber sheets may look similar to genuine carbon fiber, there are several important differences to consider:

Material Composition:

- Real Carbon Fiber: Made from woven carbon filaments that are combined with resin. The resulting material is strong, lightweight, and heat-resistant.

- Fake Carbon Fiber: Made from materials like vinyl, polyester, or fiberglass that only mimic the appearance of real carbon fiber.

- Real Carbon Fiber: Known for its high strength-to-weight ratio, carbon fiber is incredibly durable and resistant to wear, fatigue, and stress.

- Fake Carbon Fiber: Although some fake carbon fiber sheets may have good surface durability, they don’t offer the same mechanical properties as genuine carbon fiber. They may not be as strong or resistant to damage.

Weight:

- Real Carbon Fiber: Carbon fiber is famous for being extremely light. This makes it ideal for high-performance applications in automotive, aerospace, and sporting goods.

- Fake Carbon Fiber: Often heavier than real carbon fiber, especially if it's made from materials like fiberglass or plastic. This makes it unsuitable for applications where weight reduction is critical.

Cost:

- Real Carbon Fiber: Carbon fiber is expensive to produce due to the high cost of raw materials and manufacturing processes.

- Fake Carbon Fiber: Much more affordable than real carbon fiber. Vinyl wraps, for example, are typically very inexpensive compared to carbon fiber composites.

Appearance:

- Real Carbon Fiber: Has a unique, glossy finish, with the visible weave pattern of carbon fibers. It has a distinct, high-quality aesthetic that cannot be easily replicated by fake versions.

- Fake Carbon Fiber: Can imitate the appearance of real carbon fiber, but it often lacks the depth, texture, and high-gloss finish of genuine carbon fiber. Some fakes may even look artificial or plasticky.

Where to Use Fake Carbon Fiber Sheets

Fake carbon fiber sheets are ideal for applications where aesthetic appearance is more important than structural integrity or where budget constraints prevent the use of genuine carbon fiber. Some common uses include:

Automotive Customization:

- Fake carbon fiber is often used in car interiors, exteriors, and trim. Vinyl wraps, for example, can be applied to bumpers, mirrors, dashboards, or spoilers to give a sleek, sporty look without the high cost of real Carbon fiber parts.

Consumer Electronics:

- Many consumer products, such as phone cases, laptop covers, and gaming accessories, use fake carbon fiber materials for a modern, high-tech appearance. These materials are lightweight and relatively inexpensive, making them popular for such uses.

Home Decor:

- Fake carbon fiber sheets or fabrics are sometimes used for furniture, cabinetry, or decorative panels, providing a stylish and futuristic look.

DIY Projects:

- Many hobbyists and crafters use fake carbon fiber sheets for a wide range of projects, from model building to creating custom parts or accessories. Fake carbon fiber materials are easy to cut and shape, making them ideal for experimentation and custom creations.

Conclusion

While fake carbon fiber sheets may not offer the same performance as genuine carbon fiber, they provide a cost-effective alternative for projects where appearance is the primary concern. Whether you're upgrading the look of your car, enhancing your electronics, or adding a modern touch to your home decor, fake carbon fiber can give you the visual impact of real carbon fiber at a fraction of the cost. However, for applications that require strength, durability, and lightweight properties, true carbon fiber remains the superior choice.