In the world of advanced manufacturing, Carbon Fiber is the go-to material for producing lightweight, durable, and high-performance products. At the forefront of carbon fiber production, CNC cutting technology enables precise customization for a wide range of applications. Whether you're looking for carbon fiber plates, sheets, or Custom Carbon Fiber parts, factory-produced solutions offer the highest level of quality and performance.

Why Choose CNC Cutting for Custom Carbon fiber plates and Parts?

Precision Engineering with CNC Cutting:

CNC (Computer Numerical Control) cutting offers unparalleled precision, making it ideal for custom carbon fiber parts. The technology ensures that each carbon fiber plate or sheet is cut to exact specifications, minimizing material waste and maximizing efficiency. From complex shapes to standard dimensions, CNC cutting guarantees high-quality results every time.High-Quality Carbon Fiber Plates and Sheets:

Carbon fiber plates and sheets are widely used in aerospace, automotive, sports equipment, and industrial components due to their superior Strength-to-Weight Ratio. CNC cutting allows manufacturers to tailor these materials to meet specific needs, such as varying thicknesses, custom sizes, and intricate designs, ensuring they perform optimally in demanding environments.Durability and Strength for High-Performance Applications:

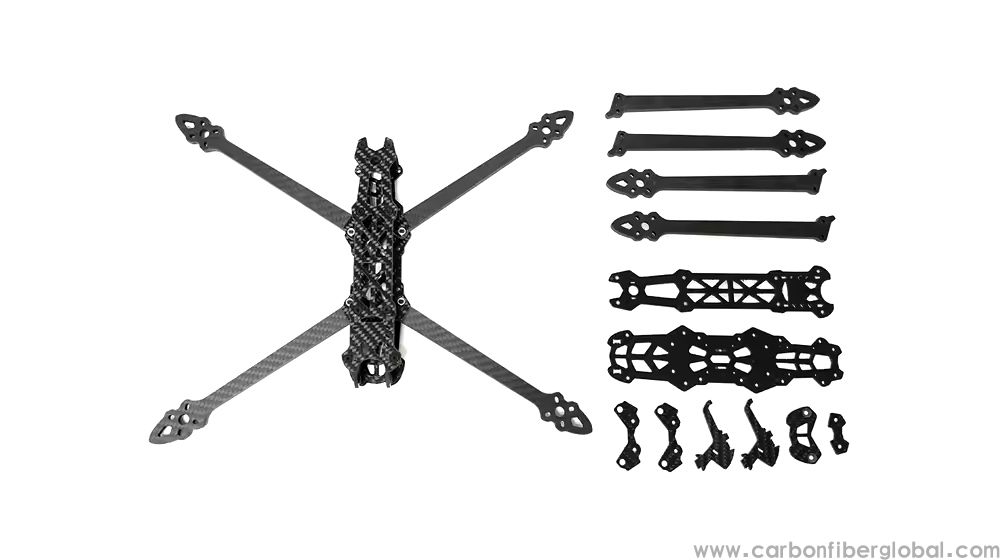

Carbon fiber is known for its exceptional strength, lightweight, and resilience, making it an ideal choice for high-performance applications. Whether you're designing drone components, automotive parts, or industrial machinery, CNC-cut carbon fiber plates and sheets provide the rigidity and stiffness needed for long-lasting performance.Customization for a Wide Range of Industries:

Factory-produced custom Carbon Fiber Products can be tailored to suit the exact requirements of a variety of industries. Whether you need thicker plates for structural reinforcement or thinner sheets for lightweight applications, CNC technology ensures you get the right material for the job. With a range of finishes, such as matte or glossy, and the option for 3K weave patterns, the design possibilities are endless.Fast Turnaround and Cost Efficiency:

CNC cutting technology allows for quick production cycles, ensuring a faster turnaround for custom projects. Factory direct production eliminates the need for intermediaries, reducing costs and delivering high-quality carbon fiber products at competitive prices. This makes CNC cutting an attractive option for businesses looking to scale their production while maintaining high standards of quality.

Applications of Custom CNC Cutting Carbon Fiber Plates, Sheets, and Parts

Aerospace and Aviation:

Custom carbon fiber plates and parts are extensively used in the aerospace industry for components such as aircraft wings, housings, and landing gear. The lightweight yet strong properties of carbon fiber help reduce fuel consumption while maintaining the required strength for structural integrity.Automotive and Motorsport:

In the automotive and motorsport industries, Carbon Fiber Sheets are used for body panels, chassis, and engine parts. The ability to cut carbon fiber into specific shapes and sizes makes it ideal for race cars and high-performance vehicles that require both strength and lightweight construction for enhanced speed and safety.Drone Manufacturing:

CNC-cut carbon fiber plates and sheets are widely used in drone frames, propellers, and other structural components. The material's strength-to-weight ratio makes it perfect for drone parts, where minimizing weight while maintaining structural stability is crucial for flight performance.Industrial and Structural Applications:

Carbon fiber is increasingly used in industrial applications such as machinery, robotics, and construction materials. Custom-cut carbon fiber parts can be designed to meet specific load-bearing requirements, offering high strength in demanding environments.Sports and Recreational Equipment:

From bicycles to golf clubs to ski poles, carbon fiber is used in the production of sports equipment that requires both strength and lightweight performance. Custom CNC cutting ensures that the carbon fiber components are perfectly tailored to the design needs of the equipment.

About Us

At Carbon Fiber Global, we specialize in factory-produced custom carbon fiber plates, sheets, and parts, utilizing advanced CNC cutting technology. Our commitment to quality and innovation has made us a trusted leader in the carbon fiber industry. With years of expertise and a dedicated team, we produce high-performance, tailored solutions for businesses across diverse sectors, including aerospace, automotive, sports, and more.

Our focus on precision, durability, and customer satisfaction ensures that every product we deliver meets the highest standards of quality. Whether you need a single custom part or large-scale production, Carbon Fiber Global is equipped to meet your needs with efficiency and excellence.