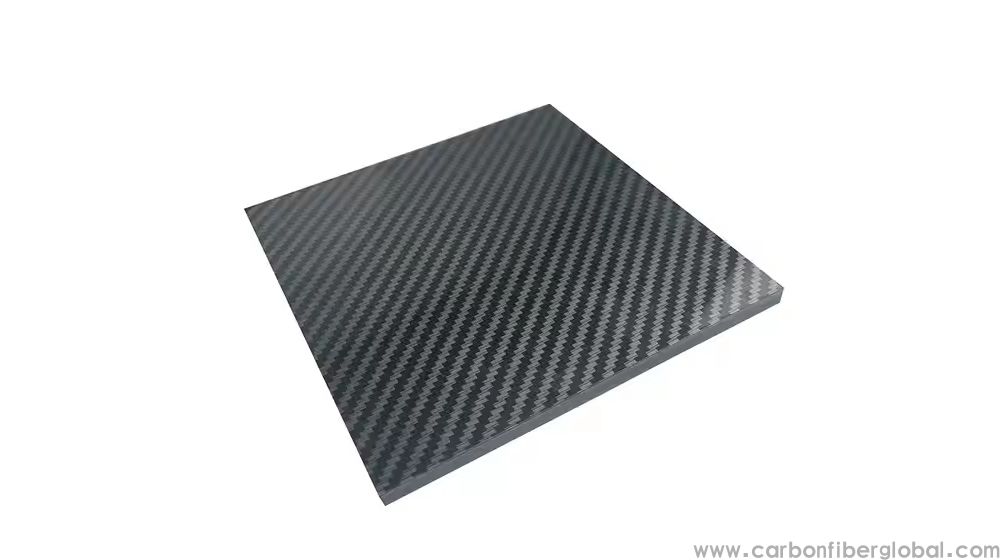

When it comes to advanced engineering, customized Carbon Fiber Sheets are increasingly being used for a variety of applications due to their exceptional performance properties. One particular variant that stands out is the 0.2mm heat-resistant Carbon Fiber sheet. This thin yet strong material is specifically engineered for environments where both high strength and resistance to elevated temperatures are critical. In this article, we'll explore the features, benefits, and common applications of 0.2mm heat-resistant Carbon fiber sheets, and why they are an excellent choice for your next project.

1. What is a 0.2mm Heat-Resistant Carbon Fiber Sheet?

A 0.2mm heat-resistant carbon fiber sheet is a specialized composite material made from High-strength carbon fibers embedded in a resin matrix. The thickness of 0.2mm makes it lightweight and flexible, while still offering the remarkable mechanical properties of carbon fiber, such as:

- High Strength-to-Weight Ratio: Carbon fiber is stronger than steel yet much lighter, making it ideal for applications where weight savings are crucial.

- Heat Resistance: This specific sheet is designed to withstand high temperatures without compromising its structural integrity, making it suitable for environments with elevated thermal stress.

- Durability: The material is resistant to fatigue, corrosion, and wear, ensuring long-term reliability even in harsh environments.

The combination of these properties makes 0.2mm heat-resistant carbon fiber sheets a go-to choice for demanding applications, particularly those that require both Lightweight design and high heat resistance.

2. Key Features of 0.2mm Heat-Resistant Carbon Fiber Sheets

- Thickness and Weight: At just 0.2mm thick, these carbon fiber sheets are extremely lightweight, providing significant weight savings without sacrificing strength. This thin profile also allows them to be used in applications requiring precision and tight tolerances.

- Heat Resistance: These sheets are made with specialized resin systems that offer superior thermal stability, enabling them to resist temperatures of up to 300°C (572°F) or higher, depending on the resin type. This makes them ideal for use in high-heat environments.

- Customizable: The sheets can be tailored to specific sizes, finishes, and reinforcement patterns (such as unidirectional or woven) to meet the precise needs of your project. Whether you need prepreg carbon fiber for advanced molding or plain weave for a sleek finish, customization is possible.

- Enhanced Structural Integrity: Despite being just 0.2mm thick, these sheets provide excellent structural strength and stiffness, ideal for reinforcing lightweight structures.

3. Benefits of Using 0.2mm Heat-Resistant Carbon Fiber Sheets

a. Exceptional Heat Resistance

One of the main reasons for choosing 0.2mm heat-resistant carbon fiber sheets is their ability to withstand high temperatures without degrading. Carbon fiber’s inherent thermal stability ensures that the material can maintain its strength and flexibility in extreme heat, making it perfect for applications in industries such as aerospace, automotive, and electronics, where heat management is essential.

b. Lightweight and Strong

Carbon fiber is renowned for its high strength-to-weight ratio, which is particularly beneficial in industries like automotive and aerospace. With a thickness of just 0.2mm, these sheets are perfect for applications where reducing weight is critical—such as in lightweight vehicle components, drone parts, and aircraft interiors. The low weight does not come at the expense of strength, as the material remains extremely durable and resistant to stress and wear.

c. Durability and Longevity

The resilience of carbon fiber ensures that these sheets can withstand environmental stressors such as vibration, moisture, and UV exposure. This longevity makes 0.2mm heat-resistant carbon fiber sheets suitable for long-term applications in demanding conditions, reducing the need for frequent maintenance or replacement.

d. Corrosion Resistance

Unlike metal-based materials, carbon fiber sheets do not suffer from corrosion due to exposure to moisture or chemicals. This makes them an excellent choice for marine environments, outdoor structures, or parts exposed to salt, chemicals, or other corrosive agents.

e. Customization Flexibility

One of the greatest advantages of using Customized carbon fiber sheets is the ability to tailor the material to your exact specifications. Whether you need a matte finish for Industrial applications or a glossy finish for consumer products, you can select the weave pattern, resin system, and dimensions that best suit your project needs.

4. Common Applications for 0.2mm Heat-Resistant Carbon Fiber Sheets

Given their strength, lightweight nature, and thermal stability, 0.2mm heat-resistant carbon fiber sheets are ideal for a variety of applications, including:

a. Automotive Industry

In the automotive industry, where lightweighting is crucial for improving fuel efficiency and performance, carbon fiber sheets are commonly used in:

- Heat shields and engine components

- Interior panels and trim elements

- Exhaust systems and brake components

The heat resistance of these sheets allows them to perform reliably under the high-heat conditions typical of automotive engines.

b. Aerospace Engineering

In aerospace, materials need to be both lightweight and able to withstand extreme temperatures. 0.2mm heat-resistant carbon fiber sheets are commonly used for:

- Aircraft fuselage panels

- Wings and tail components

- Interior components like seating and cabin fixtures

These materials help reduce the weight of aircraft, improving fuel efficiency and overall performance while maintaining structural integrity at high altitudes.

c. Electronics and Electrical Engineering

In the electronics sector, carbon fiber sheets are increasingly used for their thermal conductivity and resistance to high temperatures. Applications include:

- Heat dissipation panels in power electronics

- Circuit boards and enclosures for electronics

- Custom cooling systems for high-performance computing

The ability to resist heat without compromising strength makes carbon fiber an ideal material for heat-sensitive applications.

d. Sports Equipment

For high-performance sports equipment that must be lightweight yet extremely strong, carbon fiber sheets are used in products like:

- Bicycle frames

- Racing helmets

- Ski poles

- Golf clubs

These products benefit from carbon fiber’s strength and resilience under stress, making them ideal for performance-focused gear.

e. Marine Industry

In marine environments, where exposure to saltwater and other harsh conditions can lead to material degradation, 0.2mm heat-resistant carbon fiber sheets offer excellent corrosion resistance. These sheets are used in:

- Boat hulls

- Decks and boat interiors

- Marine structural components

Their resistance to moisture and corrosion makes them a great choice for durable marine applications.

5. How to Customize Your 0.2mm Heat-Resistant Carbon Fiber Sheets

When selecting or ordering customized carbon fiber sheets, consider the following customization options:

- Weave Type: Plain, twill, or unidirectional—each type provides a different combination of strength, flexibility, and aesthetic appeal.

- Resin System: Epoxy resin is commonly used for heat-resistant applications, offering superior thermal stability and durability.

- Surface Finish: Choose from matte, glossy, or textured finishes depending on your desired aesthetic and functionality.

- Cutting and Shaping: Many carbon fiber sheets can be pre-cut or molded to fit your project’s exact specifications, making them easy to integrate into your design.

Conclusion

0.2mm heat-resistant carbon fiber sheets are a versatile and high-performance material perfect for projects that require both lightweight design and superior heat resistance. Whether you’re working on aerospace components, automotive parts, electronics, or marine applications, these sheets offer strength, durability, and thermal stability that meet the most demanding requirements. With customization options available, you can tailor the material to your specific needs, ensuring the best performance for your project.