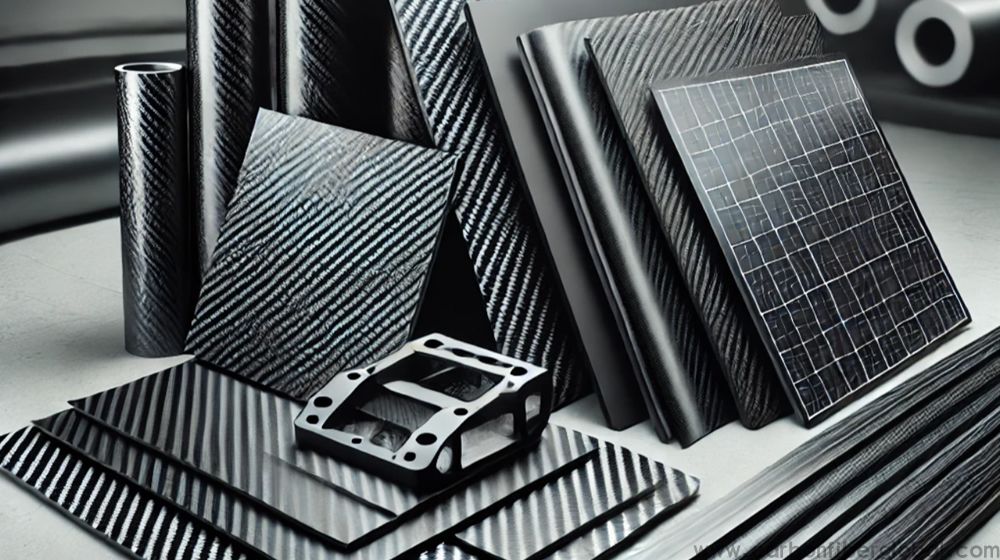

In the world of marine engineering, the pursuit of materials that combine strength, lightweight properties, and resilience is vital for creating high-performance vessels that can withstand harsh oceanic conditions. Among the most promising materials to meet these demanding needs is Carbon Fiber. Known for its remarkable Strength-to-Weight Ratio, Carbon Fiber Sheets have become increasingly popular in marine applications, from yacht construction to underwater robotics. In this article, we explore how Carbon fiber sheets contribute to enhanced durability and performance in the marine industry.

1. Unmatched Strength-to-Weight Ratio

One of the primary reasons carbon fiber is a preferred material in the marine industry is its strength-to-weight ratio. Carbon fiber sheets are incredibly strong yet lightweight, making them ideal for applications where reducing weight without sacrificing structural integrity is crucial. In marine environments, weight reduction can significantly improve a vessel's performance, from faster speeds to increased fuel efficiency.

For example, racing yachts and high-performance boats benefit greatly from carbon fiber’s lightweight properties. With lighter structures, these vessels can achieve higher speeds while consuming less energy, giving them a competitive edge in speed races. Additionally, lighter vessels tend to experience less drag in the water, which translates to better maneuverability and overall handling.

- Key Advantage: Lighter boats with improved performance and fuel efficiency.

2. Superior Durability and Resistance to Corrosion

Marine environments are notoriously harsh, with exposure to saltwater, UV rays, and extreme weather conditions. Traditional materials such as metals often suffer from corrosion, leading to a decrease in performance and lifespan. However, carbon fiber sheets are highly resistant to corrosion, ensuring a longer service life in marine applications.

Unlike metals, carbon fiber does not rust or degrade when exposed to saltwater, making it a durable choice for boats, ships, and marine structures that operate in coastal or offshore environments. The resilience of carbon fiber helps to ensure the integrity of the vessel, even in challenging conditions such as saltwater immersion, which would typically accelerate the deterioration of materials like steel or aluminum.

- Key Advantage: Increased lifespan of marine vessels with reduced maintenance costs.

3. Resistance to Impact and Fatigue

The marine environment is full of dynamic forces that can put a lot of stress on vessels. From waves crashing against the hull to the constant vibrations caused by the engine and water movement, the materials used in boats and ships must be able to withstand impact and fatigue.

Carbon fiber sheets excel in this regard. They are not only strong but also flexible enough to absorb shock and impact without breaking. This makes them particularly well-suited for applications such as hull construction or reinforcement in areas prone to physical stress. In addition to their impact resistance, carbon fiber’s unique properties allow it to tolerate fatigue from repetitive stress, such as the forces acting on a boat’s deck or structure during long-term use.

This impact resistance is particularly critical for vessels that operate in rough waters, where the risk of collisions or damage from waves is ever-present. Carbon fiber offers a high degree of protection without adding unnecessary weight, making it an ideal material for durable and safe marine structures.

- Key Advantage: Vessels that resist damage from impact, collisions, and long-term use in tough marine environments.

4. Enhanced Hydrodynamics

In marine applications, hydrodynamic performance is a key factor in determining a vessel’s speed, fuel efficiency, and handling capabilities. The design of a vessel’s hull and surface materials play a significant role in reducing drag and enhancing performance.

Carbon fiber sheets can be molded and shaped to create streamlined, smooth surfaces that minimize drag as the vessel moves through the water. By reducing friction between the hull and water, carbon fiber not only increases speed but also contributes to better fuel efficiency, which is especially important in commercial vessels and recreational boats.

Whether it’s racing yachts that need to achieve maximum velocity or recreational boats that require ease of movement through the water, carbon fiber provides the performance benefits needed to enhance hydrodynamics and ensure smooth sailing.

- Key Advantage: Smoother, more efficient movement through water with reduced drag.

5. UV Resistance and Aesthetic Appeal

Marine vessels are constantly exposed to the sun’s ultraviolet (UV) rays, which can cause degradation in materials like plastic, rubber, and wood over time. Carbon fiber sheets are naturally resistant to UV radiation, meaning that they retain their structural integrity and aesthetic appearance even after prolonged exposure to the sun.

In addition to their functional properties, carbon fiber sheets also add a unique aesthetic appeal to marine vessels. The distinctive weave pattern and sleek, modern look of carbon fiber are often incorporated into luxury yachts and high-performance boats, contributing to a stylish appearance that reflects both elegance and advanced technology.

- Key Advantage: Vessels that retain their appearance and functionality despite prolonged sun exposure.

6. Customization for Specialized Marine Applications

The versatility of carbon fiber sheets allows for Tailored solutions in marine applications. Whether it’s creating bespoke yacht interiors, custom components for underwater robots, or reinforced hulls, carbon fiber can be molded into a variety of shapes and sizes to meet specific design requirements.

For example, underwater vehicles or drones that require a material that can withstand deep-sea pressures and resist corrosion often benefit from custom-made Carbon Fiber Components. These components can be designed with the exact specifications needed to perform under specific conditions, ensuring the longevity and reliability of the equipment.

- Key Advantage: Custom-built solutions for unique marine projects and applications.

7. Sustainability and Eco-Friendliness

With growing concerns about environmental impact, many industries, including marine, are focusing on using Sustainable Materials. Carbon fiber, though traditionally known for being expensive, offers the advantage of a long lifespan and can be recycled at the end of its life cycle. As a result, its environmental footprint is reduced compared to other materials that need frequent replacement or maintenance.

By using carbon fiber in marine applications, manufacturers can contribute to more eco-friendly designs, particularly in industries like yacht building or commercial shipping, where longevity and durability reduce the need for constant repairs and replacements.

- Key Advantage: Eco-friendly material choice that promotes sustainability in marine industry.

8. Reduced Maintenance and Repair Costs

Thanks to carbon fiber’s resistance to corrosion, impact, and UV degradation, vessels built with carbon fiber require less maintenance and fewer repairs over their lifespan. This makes it a cost-effective solution in the long term, as boat owners and marine operators spend less money on repairs and maintenance.

The reduced need for maintenance is especially valuable for commercial ships or recreational boats that are exposed to the elements year-round. The durability of carbon fiber sheets helps minimize downtime and extends the operational life of the vessel.

- Key Advantage: Reduced maintenance and repair costs for marine vessels over time.

Conclusion

Carbon fiber sheets provide a host of benefits that make them the perfect material for marine applications, from enhancing performance and durability to offering aesthetic appeal and environmental sustainability. Whether for luxury yachts, commercial vessels, or underwater robotics, carbon fiber’s combination of strength, lightweight properties, and resistance to harsh marine conditions makes it a game-changer in the maritime industry. By integrating carbon fiber into marine design and construction, manufacturers and boat owners can enjoy vessels that are faster, more durable, and more cost-effective over time.