In the automotive industry, Carbon Fiber Sheets are transforming how vehicles are designed, built, and driven. Known for their exceptional strength, lightweight properties, and high durability, Carbon Fiber sheets are quickly becoming a preferred material for manufacturers aiming to enhance vehicle performance while reducing weight. This shift to carbon fiber is revolutionizing the way cars are built, leading to faster, safer, and more efficient vehicles. In this article, we explore how Carbon fiber sheets are revolutionizing the automotive industry and why they are essential for the future of vehicle performance and design.

1. Lightweight and High-Strength Performance

One of the most significant advantages of carbon fiber sheets is their lightweight nature. In automotive design, reducing weight is crucial for improving fuel efficiency, acceleration, and handling. Carbon fiber offers a remarkable Strength-to-Weight Ratio, meaning it is significantly lighter than traditional metals like steel or aluminum while providing equal or even superior strength.

By replacing heavier materials with carbon fiber, manufacturers can reduce the overall weight of vehicles, which leads to improved fuel efficiency and lower emissions. This is especially beneficial for electric vehicles (EVs), where reducing weight directly increases the driving range per charge. Whether it's used for body panels, chassis components, or interior elements, carbon fiber is helping automotive engineers design vehicles that are both high-performance and eco-friendly.

2. Enhanced Safety and Durability

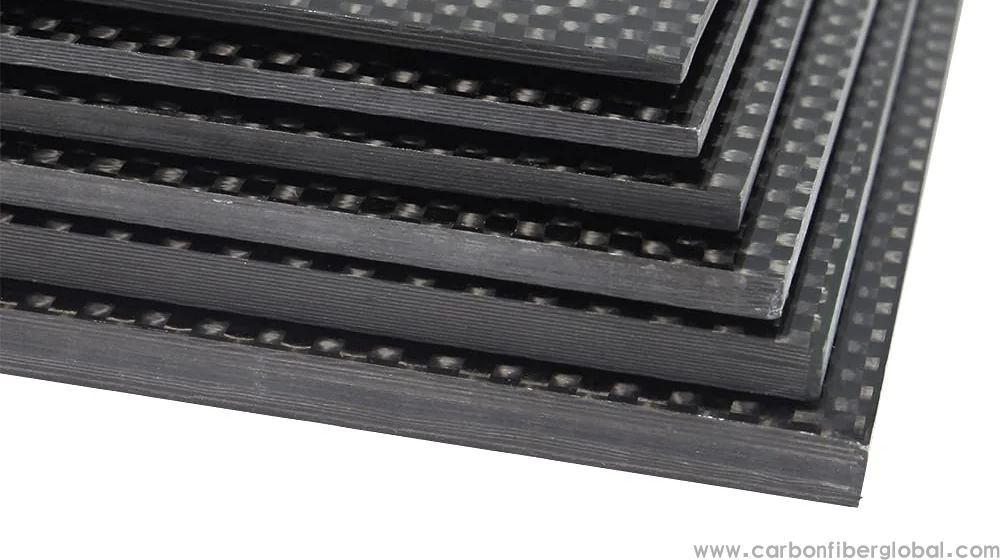

Another key benefit of carbon fiber sheets is their exceptional durability and impact resistance. Carbon fiber’s unique weave structure allows it to absorb and dissipate energy, making it an ideal material for safety-critical Automotive Components. In the event of a collision, carbon fiber can help reduce the impact force transferred to passengers, potentially improving crash safety.

Moreover, carbon fiber is resistant to corrosion, which ensures that automotive parts made from this material will last longer compared to traditional metal components. This durability makes carbon fiber sheets ideal for both exterior and structural parts of the vehicle, including body panels, fenders, and even the car's undercarriage.

3. Streamlined Manufacturing and Design flexibility

Carbon fiber sheets offer immense design flexibility, allowing automotive designers to create more complex shapes and structures that would be difficult or impossible to achieve with Traditional materials. The ability to mold carbon fiber into precise shapes helps manufacturers optimize vehicle aerodynamics and aesthetics. Additionally, carbon fiber's versatility opens up new possibilities for custom vehicle design, including the use of carbon fiber in interior elements such as dashboards, seats, and trims.

In terms of manufacturing, carbon fiber has seen improvements in cost-effectiveness, making it more accessible to mainstream automotive production. With advances in manufacturing techniques, such as prepreg and resin infusion, Carbon Fiber Components are now being produced with greater efficiency, reducing the overall cost and time needed for production. This enables more automakers to integrate carbon fiber into their designs without significant increases in cost.

4. Future of Carbon Fiber in Automotive Design

As the automotive industry continues to push toward sustainability and higher performance, the demand for carbon fiber is expected to grow. The material is not only enhancing traditional vehicles but is also becoming a key player in the development of electric vehicles (EVs) and autonomous vehicles (AVs), where weight reduction and high strength are paramount.

In the future, carbon fiber is likely to play an even bigger role in the development of lightweight, fuel-efficient vehicles, especially as innovations in production technology continue to drive down costs. More automotive manufacturers are already experimenting with carbon fiber in production cars, from sports cars to luxury sedans, and the material will continue to push the boundaries of what’s possible in vehicle design.