In industries where performance, strength, and durability are paramount, Carbon Fiber Sheets have become a game-changing material. From aerospace to automotive and sports equipment, Carbon Fiber’s unique combination of lightweight properties and unmatched strength is driving innovation and efficiency across various sectors. This article explores why Carbon fiber sheets are considered the ideal solution for creating lightweight and durable components.

1. The Exceptional Strength-to-Weight Ratio

One of the most remarkable qualities of carbon fiber sheets is their exceptional strength-to-weight ratio. Carbon fiber is stronger than steel but only a fraction of its weight, which makes it an ideal material for applications that demand both strength and Lightweight design. This characteristic is particularly advantageous in industries where performance is closely linked to weight, such as in aerospace and automotive manufacturing.

In aerospace, for example, carbon fiber sheets are used to reduce the overall weight of aircraft without compromising structural integrity. A lighter aircraft can achieve better fuel efficiency, lower operating costs, and enhanced aerodynamic performance. Similarly, in the automotive sector, using Carbon fiber parts such as body panels, frames, and chassis helps manufacturers produce lighter vehicles that are more fuel-efficient and faster while improving handling and safety.

2. Durability and Resistance to Wear

Another key benefit of carbon fiber sheets is their outstanding durability. Carbon fiber is highly resistant to wear, fatigue, and corrosion, which makes it ideal for components subjected to extreme stress, harsh environments, and high usage rates.

In the sports equipment industry, for example, carbon fiber is commonly used in bicycles, skateboards, golf clubs, and tennis rackets. These products benefit from carbon fiber’s ability to withstand constant wear and tear while maintaining strength and stiffness. Carbon fiber also resists corrosion and rust, which is an advantage for parts exposed to elements like rain or saltwater.

In Industrial applications, where parts are exposed to vibrations, impacts, and heavy use, carbon fiber sheets provide long-lasting performance without the risk of deformation or failure that often occurs with metals over time. This resistance to wear makes carbon fiber an invaluable material for machinery components, robotics, and structural components that need to endure repeated stress and harsh environments.

3. Temperature Resistance

Carbon fiber sheets are also known for their excellent heat resistance. Unlike metals, which can expand, contract, or warp under extreme temperatures, carbon fiber maintains its structural integrity even in very high or low temperatures. This makes it especially suitable for industries like aerospace, automotive, and electronics.

In aerospace, for example, carbon fiber is used in components like heat shields, wing structures, and engine nacelles, where parts need to withstand high temperatures during takeoff, flight, and landing. Carbon fiber’s ability to retain its form and strength despite exposure to intense heat makes it crucial in these high-performance environments.

In automotive racing, carbon fiber’s resistance to heat is also crucial, as it ensures that components like brake pads and engine covers can perform at their best without degrading due to high temperatures.

4. Customization for Specific Applications

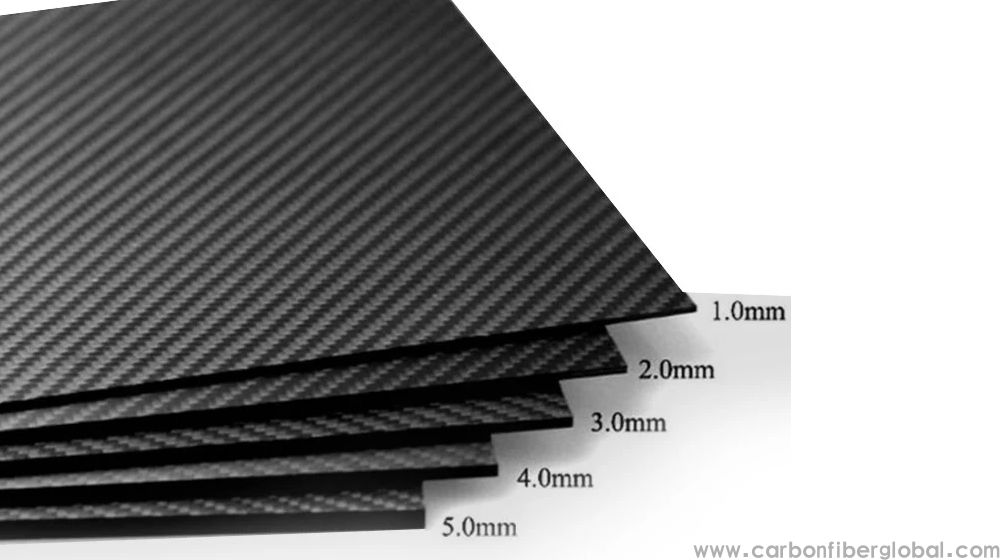

Another compelling advantage of carbon fiber sheets is their versatility and ability to be customized for specific applications. Carbon fiber sheets can be molded into a variety of shapes and sizes to suit a wide range of performance requirements. This customization allows manufacturers to produce components that meet exact specifications, whether they need enhanced stiffness, greater flexibility, or optimized aerodynamics.

In the sports equipment industry, for example, manufacturers can design bicycles with carbon fiber frames that are lightweight and strong, or golf clubs with shafts that offer the perfect combination of flexibility and strength. Custom carbon fiber sheets can be tailored to meet the specific performance needs of athletes, giving them an edge in competitions.

Similarly, in aerospace and automotive design, engineers can mold carbon fiber sheets into highly complex shapes to achieve improved aerodynamics, reduced drag, and enhanced structural strength. Whether designing aircraft wings, vehicle body panels, or automotive interiors, carbon fiber offers the flexibility to meet the diverse demands of these industries.

5. Sustainability and Environmental Benefits

While carbon fiber sheets have traditionally been used in high-performance industries, their growing demand is also tied to the increasing focus on sustainability and eco-friendly practices. Carbon fiber’s lightweight nature helps reduce fuel consumption, making it an essential material for industries like aerospace and automotive, where energy efficiency and carbon emissions are key considerations.

In automotive manufacturing, for example, the use of Lightweight Carbon Fiber components leads to improved fuel economy and reduced carbon emissions, helping manufacturers meet environmental standards and regulations. In aerospace, carbon fiber is used to build more fuel-efficient aircraft, which contributes to reducing the aviation industry’s overall carbon footprint.

Furthermore, advancements in carbon fiber recycling are making it easier for manufacturers to reduce waste and reuse materials, which aligns with the growing emphasis on sustainability. By recycling carbon fiber, industries can minimize environmental impact while still benefiting from the material’s performance advantages.