Carbon Fiber Kevlar sheets combine the unique properties of two advanced materials: the incredible strength and rigidity of carbon fiber with the flexibility and impact resistance of Kevlar. This hybrid material is a game-changer for industries that require lightweight yet durable solutions capable of withstanding high-impact conditions.

Key Features of carbon fiber kevlar sheets

Superior Strength-to-Weight Ratio

Carbon fiber provides unmatched stiffness and strength, while Kevlar adds toughness and flexibility. Together, they create a sheet that is lightweight yet robust enough for demanding applications.Impact Resistance

Kevlar fibers excel in absorbing impacts, making these hybrid sheets highly resistant to cracking or breaking under stress. This feature is especially important in industries such as aerospace and motorsports.Durability

Carbon fiber Kevlar sheets are resistant to corrosion, temperature extremes, and UV exposure, ensuring long-lasting performance in challenging environments.Aesthetic Appeal

The woven patterns of carbon fiber and Kevlar create a striking visual effect, offering a unique aesthetic that combines functionality with style.

Applications of carbon fiber Kevlar Sheets

Aerospace

Ideal for creating lightweight, impact-resistant components for aircraft interiors, UAVs, and protective gear.Automotive and Motorsports

Commonly used for body panels, undercarriage protection, and custom parts that need both rigidity and shock absorption.Marine

Suited for hull reinforcements and boat components exposed to harsh environments and high impacts.Sports Equipment

Popular in manufacturing protective gear, such as helmets, as well as high-performance equipment like racing bicycles and kayaks.Industrial applications

Used in tool manufacturing, vibration-resistant panels, and protective barriers in industrial machinery.

How to Work with Carbon Fiber Kevlar Sheets

Cutting these hybrid sheets requires precision tools, such as diamond-coated or carbide blades. Kevlar’s tough fibers can be challenging to cut cleanly, so proper equipment and technique are essential. Adhesives like epoxy work best for bonding, ensuring a secure and durable attachment.

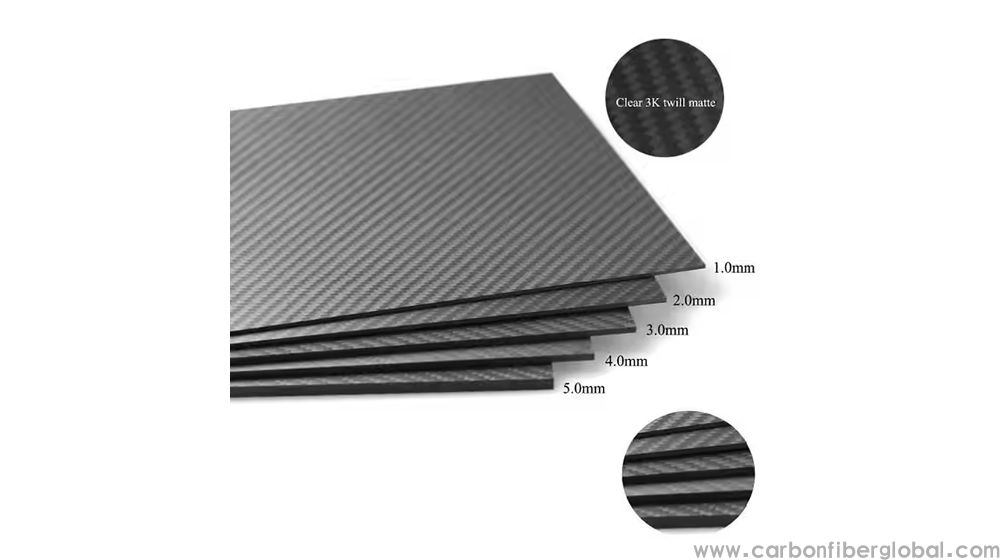

Choosing the Right Sheet

When selecting a carbon fiber Kevlar sheet, consider the ratio of carbon fiber to Kevlar in the weave. Sheets with more Kevlar offer greater impact resistance and flexibility, while those with a higher carbon fiber content are stiffer and more rigid. Also, pay attention to the sheet’s thickness and finish to match your specific project needs.

Where to Buy Carbon Fiber Kevlar Sheets

These sheets are available from specialty composite material suppliers and online platforms. Reputable manufacturers provide detailed product specifications and offer custom options for unique applications.

Conclusion

Carbon fiber Kevlar sheets are a versatile and high-performance material that brings together the best properties of carbon fiber and Kevlar. Their combination of strength, flexibility, and durability makes them an ideal choice for a wide range of industries. Whether you're crafting aerospace components or designing protective gear, these hybrid sheets offer the perfect balance of functionality and style.