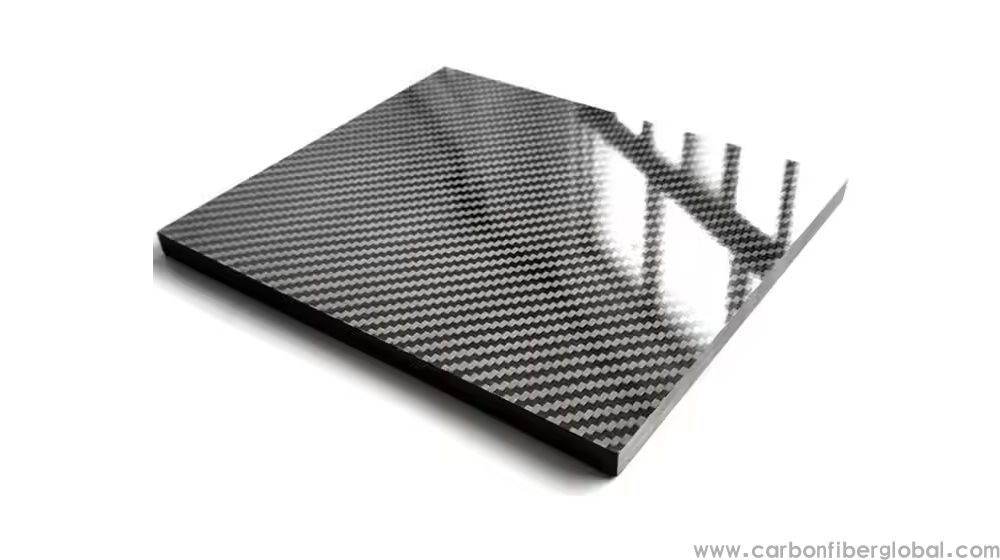

Carbon Fiber composite sheets are engineered materials made by combining carbon fibers with a resin matrix to create a strong, lightweight, and durable sheet. These sheets are widely used across many industries, including aerospace, automotive, marine, and construction, due to their remarkable Strength-to-Weight Ratio, flexibility, and resistance to environmental factors.

Key Features of carbon fiber composite sheets

Exceptional Strength-to-Weight RatioCarbon fiber composites are known for their outstanding strength-to-weight ratio. They are significantly lighter than metals like steel and aluminum, but much stronger. This makes them ideal for applications that require both high strength and minimal weight.

High RigidityThese sheets are stiff and resistant to bending, which makes them suitable for structural components that need to maintain their shape under stress.

Corrosion ResistanceCarbon fiber composites are resistant to corrosion from moisture, chemicals, and UV light. This makes them especially useful in environments where Traditional materials may degrade.

Thermal StabilityThe material can withstand high temperatures without losing its structural integrity, making it ideal for applications in extreme environments, such as aerospace or automotive industries.

Customizable PropertiesThe properties of carbon fiber composites can be tailored depending on the type of resin used, the fiber orientation, and the weave pattern. This customization allows for more flexibility in design and engineering.

Common Applications of carbon fiber Composite Sheets

Aerospace and AviationCarbon fiber composites are used extensively in the aerospace industry for building lightweight, strong components like fuselages, wings, and interior panels. The high strength-to-weight ratio of carbon fiber is crucial for reducing aircraft weight and improving fuel efficiency.

AutomotiveIn automotive manufacturing, carbon fiber composite sheets are used for parts like body panels, chassis components, and interior trim. The use of carbon fiber composites in cars can significantly reduce weight while maintaining strength, improving speed and fuel efficiency.

MarineCarbon fiber composites are used in boat hulls, masts, and other marine applications. Their high resistance to corrosion and water absorption makes them ideal for use in harsh marine environments.

Sports EquipmentMany sports equipment manufacturers use carbon fiber composite sheets to make lightweight, durable products such as bicycles, golf clubs, tennis rackets, and skis. The material’s stiffness and lightweight nature improve performance in these products.

Construction and ArchitectureCarbon fiber composite sheets are used for reinforcement and repair of existing structures, such as bridges and buildings, as they provide high tensile strength and can be applied in thin layers, minimizing weight.

Benefits of Carbon Fiber Composite Sheets

DurabilityCarbon fiber composite sheets have long lifespans and can withstand harsh environmental conditions. They resist corrosion, impact, and UV degradation, which makes them reliable in outdoor and high-performance applications.

Design flexibilityThe material can be molded into complex shapes, making it suitable for custom applications in a wide range of industries. Carbon Fiber Sheets can be laid out in various weaves and orientations to optimize strength in different directions.

Reduced Maintenance CostsDue to their durability and resistance to wear and corrosion, carbon fiber composite materials require less maintenance compared to metals or traditional materials, resulting in lower overall costs.

Improved PerformanceThe reduced weight of carbon fiber composite sheets allows for better fuel efficiency, higher speeds, and improved handling, particularly in the automotive and aerospace industries.

How to Work with Carbon Fiber Composite Sheets

Cutting

- Use specialized tools such as diamond-tipped or carbide blades for Cutting Carbon Fiber composite sheets. Avoid using regular tools like wood saws, as they may cause fraying.

- Carbon fiber sheets should be cut on a solid surface with the right amount of pressure to avoid damaging the material.

Drilling

- When drilling into carbon fiber composites, use a high-quality, sharp drill bit designed for composite materials.

- Slow speeds and low pressure are important to avoid delamination and to achieve a clean hole.

Bonding

- For adhesion, epoxy resin or specialized composite adhesives are typically used. Make sure to properly clean and prepare the surfaces for bonding to ensure maximum strength.

Finishing

- After cutting and drilling, sand the edges with fine-grit sandpaper to achieve smooth, clean finishes. Be sure to wear a mask to protect against inhaling carbon fiber dust.

- Clear coatings can be applied to enhance the finish and provide an additional layer of protection.

Where to Buy Carbon Fiber Composite Sheets

Carbon fiber composite sheets are available from various suppliers specializing in advanced materials and composites, such as:

- Rock West Composites

- DragonPlate

- Protech Composites

- McMaster-Carr

These companies offer a wide range of composite sheets with varying thicknesses, weaves, and resin types for different applications.

Conclusion

Carbon fiber composite sheets are essential for applications requiring high strength, lightweight properties, and resistance to environmental factors. Whether in aerospace, automotive, sports, or construction, these sheets provide superior performance and versatility. By choosing the right grade of carbon fiber composite material for your needs, you can enhance the efficiency and durability of your projects, leading to long-term benefits and cost savings.