Carbon Fiber Sheets are known for their exceptional strength, lightweight nature, and versatility, making them an ideal choice for a wide range of applications. When it comes to larger formats, the 12x12 Carbon Fiber sheet stands out as a popular option. These sheets provide ample surface area while maintaining the key characteristics that make carbon fiber such a sought-after material. Whether you're working on Aerospace Engineering, automotive parts, sporting goods, or custom design projects, 12x12 Carbon fiber sheets are an excellent material choice for many industries.

What Are 12x12 Carbon Fiber Sheets?

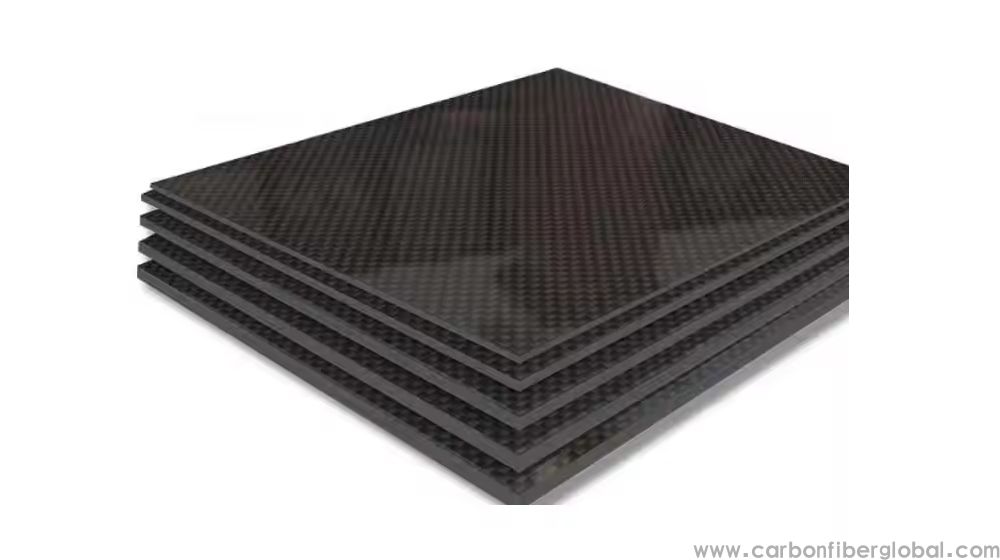

A 12x12 carbon fiber sheet refers to a carbon fiber composite material that is square-shaped, with each side measuring 12 inches (approximately 30.48 cm). These sheets are typically made by layering carbon fiber fabrics, which are impregnated with resin and cured under heat and pressure. The result is a rigid, strong, and durable composite material that can be used for various purposes.

The sheet's size and thickness can vary, with common thicknesses including 0.5mm, 1mm, 2mm, or even 5mm depending on the needs of the project. The flexibility to cut and customize these sheets makes them versatile for both small and large-scale applications.

Properties of 12x12 Carbon Fiber Sheets

High Strength-to-Weight Ratio: Carbon fiber is well-known for its remarkable strength relative to its low weight. 12x12 sheets maintain this property, allowing for enhanced performance without adding unnecessary weight. This feature is particularly beneficial for industries like aerospace, automotive, and sports equipment manufacturing.

Durability: Carbon fiber sheets are extremely durable and resistant to damage. They are highly resistant to scratches, dents, and impact, which makes them ideal for parts that must withstand harsh environments or heavy use.

Corrosion Resistance: Unlike metals, carbon fiber sheets do not corrode, making them an ideal choice for marine, chemical, or outdoor applications where exposure to the elements is inevitable.

Thermal Stability: Carbon fiber materials have a high resistance to temperature extremes. This makes 12x12 carbon fiber sheets suitable for applications in high-temperature environments, such as industrial machinery or aerospace components.

Electrical Conductivity: While carbon fiber is generally a conductor, the level of conductivity can vary based on the resin used. In certain cases, this can be beneficial for applications requiring electrostatic dissipation.

Flexibility for Customization: The sheets can be easily cut, drilled, or shaped to meet the specific requirements of any project. This flexibility makes them ideal for both prototyping and final production.

Applications of 12x12 Carbon Fiber Sheets

Aerospace and Aviation: In the aerospace industry, 12x12 carbon fiber sheets are used to create structural components such as fuselages, wings, and tail sections. The high strength and low weight of carbon fiber make it perfect for reducing overall aircraft weight without sacrificing durability and performance.

Automotive: Carbon fiber is widely used in high-performance vehicles, including motorsports, luxury cars, and custom builds. 12x12 carbon fiber sheets are used to create lightweight body panels, spoilers, hoods, and reinforcement parts that improve speed, fuel efficiency, and handling.

Sports Equipment: The strength, lightness, and rigidity of carbon fiber sheets make them a popular material for sporting goods. 12x12 carbon fiber sheets are used to make bicycle frames, skis, snowboards, golf clubs, and other equipment, giving athletes a competitive edge due to reduced weight and increased durability.

Marine Industry: For marine applications, carbon fiber offers exceptional resistance to corrosion from saltwater. 12x12 sheets are used for boat hulls, deck reinforcements, and structural parts that require both strength and lightweight properties for enhanced performance.

Custom Parts and Prototyping: The 12x12 carbon fiber sheet size is ideal for creating custom parts and prototypes in industries such as robotics, industrial machinery, and electronics. Designers often use these sheets to create specialized components that need to be both strong and lightweight.

Military and Defense: The military uses carbon fiber for its combination of strength and lightweight properties. 12x12 carbon fiber sheets are commonly used in drone components, armored vehicles, and protective equipment, where both protection and weight reduction are crucial.

Architectural and Construction Applications: In architecture and construction, carbon fiber sheets are used for reinforcement in concrete structures and as part of facades for aesthetic appeal and durability. The 12x12 sheet size is commonly used for smaller-scale applications or where space constraints are a factor.

Medical Devices: Some medical equipment, such as prosthetics and assistive devices, benefit from the lightweight and durable properties of carbon fiber. 12x12 carbon fiber sheets can be used to create durable, customized medical components.

Advantages of 12x12 Carbon Fiber Sheets

High Performance: The high-performance properties of carbon fiber, including its exceptional strength-to-weight ratio, make the 12x12 sheets an excellent choice for industries where performance and durability are key.

Cost-Effective for Custom Projects: While carbon fiber can be expensive, using 12x12 sheets allows manufacturers and designers to cut and customize the material to suit their exact needs. This minimizes waste and ensures that projects are more cost-effective.

Ease of Handling: The 12x12 sheet size is large enough to be used for significant projects while remaining manageable for cutting, handling, and shipping. This makes it a versatile option for both small-scale and large-scale applications.

Versatility: 12x12 carbon fiber sheets are suitable for a wide range of applications, from high-performance components to decorative and structural elements. The material's flexibility makes it adaptable to various industries and needs.

Enhanced Design flexibility: Carbon fiber's unique aesthetic—its glossy finish and weave pattern—adds a high-end look to products. 12x12 sheets can be used to create stylish and functional components in consumer goods and Industrial applications.

How to Work with 12x12 Carbon Fiber Sheets

Cutting: cutting carbon fiber sheets requires specialized tools such as a diamond saw, rotary cutter, or laser cutter. When cutting 12x12 sheets, it is important to work in a well-ventilated area and use protective equipment to avoid inhaling carbon fiber dust.

Drilling: Use carbide-tipped drill bits at slow speeds to prevent delamination when drilling holes in carbon fiber sheets. Backing the sheet with a soft material can help reduce stress and damage during the drilling process.

Sanding and Finishing: Sanding carbon fiber sheets should be done with wet sanding techniques to avoid creating dust. Fine-grit sandpaper should be used to smooth edges and ensure the surface is smooth and polished.

Bonding: Carbon fiber sheets can be bonded using strong epoxy resins. Proper surface preparation is essential for optimal bonding, so cleaning the surface thoroughly before application is crucial.

Conclusion

The 12x12 carbon fiber sheet is a versatile and high-performance material that offers a range of benefits across many industries. Its strength, lightweight properties, durability, and ease of customization make it an excellent choice for applications in aerospace, automotive, marine, sports equipment, and more. Whether used for high-performance structural components or custom projects, 12x12 carbon fiber sheets provide a combination of superior mechanical properties and aesthetic appeal that is hard to beat. As demand for carbon fiber continues to grow across various sectors, the 12x12 sheet format remains a highly practical and effective solution for many professional applications.